Focus

Line-scanning data captured by the AIVR Focus system provides an incredibly comprehensive capture of the track using underbody cameras, enhancing early detection of railway track anomalies and facilitating proactive maintenance to reduce faults on the tracks and prevent track wear and tear.

A Line Scanning System

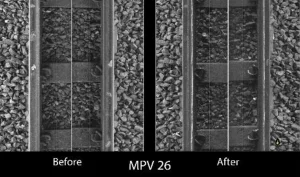

AIVR Focus, a state-of-the-art Line Scanning system deployed on in-service and measurement vehicles, automatically captures and detects track conditions on conductor and plain track. This enables automated railway track inspection, allowing remote, detailed inspection using a safe, rapid, and reliable method.

This proactive maintenance approach helps to reduce catastrophic failure through earlier fault detection, which is critical for reducing operational disruptions and maximising performance.

Inspect Track Conditions on the AIVR Platform

AIVR Platform‘s specialist interface allows engineers to examine the areas of track they need to see.

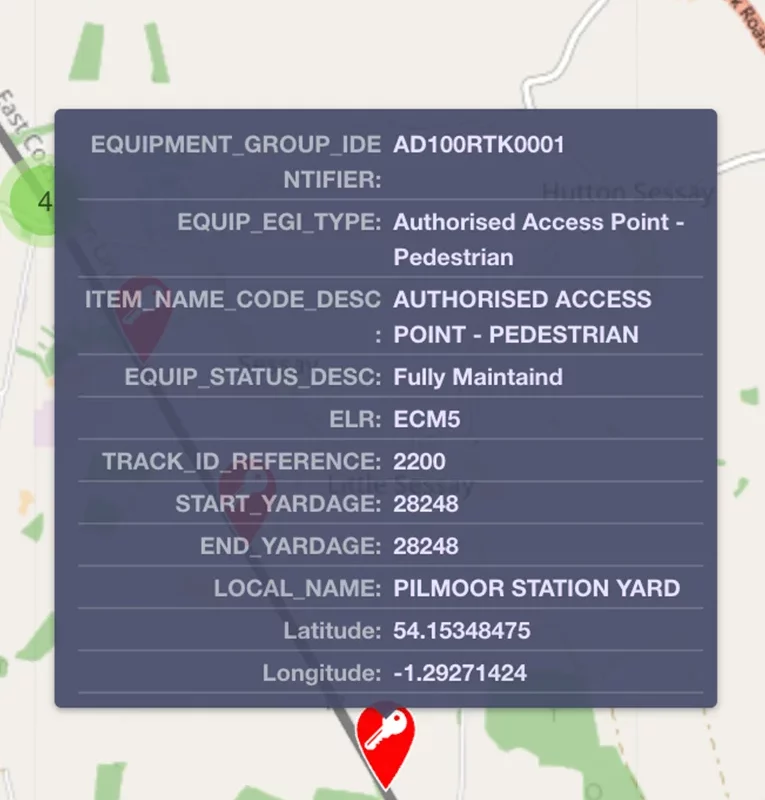

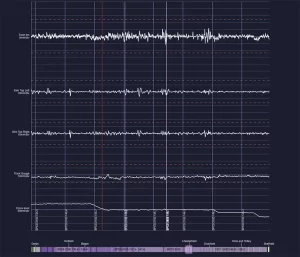

AIVR Focus provides a complete package for engineers with a combination of data from Forward-Facing, Line-Scanning, Geospatial and additional Partner Location Systems, to precisely locate defects, assess track conditions and monitor change or deterioration over time.

This comprehensive approach to defect detection and localision improves the safety and reliability of rail travel, enabling maintenance teams to target specific areas for rapid response, thereby optimising maintenance schedules and resource allocation of resource.

Using AIVR, maintenance teams can make data-driven decisions to support track access planning, with the ability to export key data via spreadsheets and other open formats for teams to review and share.

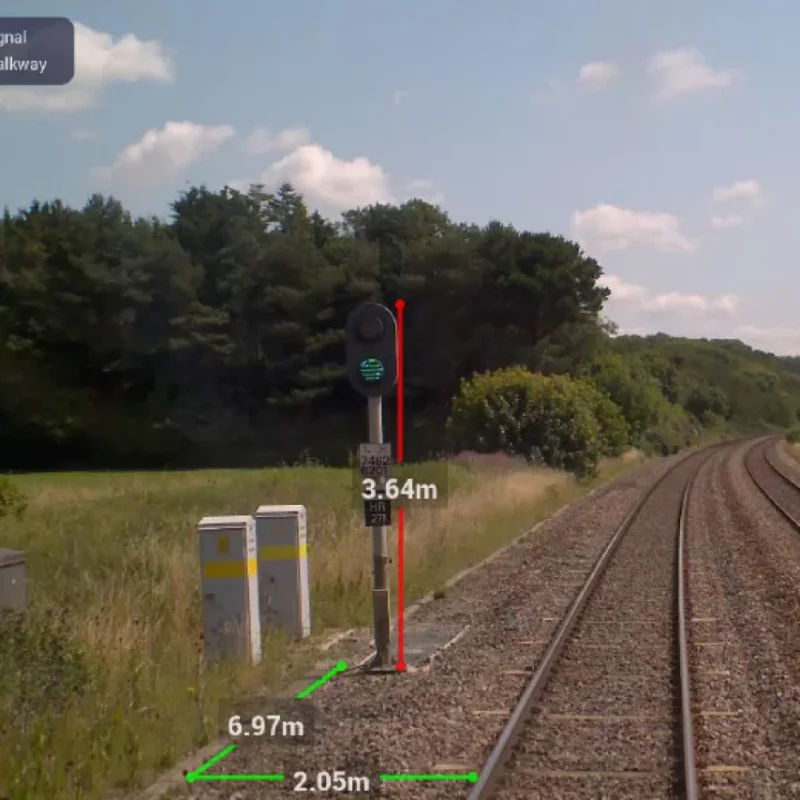

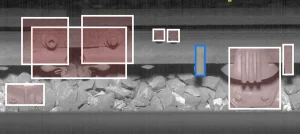

Track Componentry Detection

Machine Learning developed with industry rail experts is applied to the high-definition imagery to enable the automatic detection of key track components such as fishplates, electrical cables, joints, welds, and other critical points of interest.

This advanced technology assesses the conditions of these assets and identifies potential ‘issues’ for further investigation, playing a crucial role in predicting railway track faults. By assessing the conditions of these assets and identifying potential ‘issues’ for further investigation, the system contributes significantly to the longevity of track components and helps in avoiding costly emergency repairs.

Low Adhesion Monitoring

An automated system on in-service vehicles that provides imagery and location information to enable digital examination of areas of railhead contamination.

Track Geometry

The integration of laser-based track geometry systems operates autonomously with AIVR. Data is made accessible via our powerful web-based frontend, alongside AIVR’s captured line-scanning imagery, optimising railway track geometry analysis. Geometry data is provided in Network Rail specific presentation.

The AIVR Focus system consists of:

- Underbody cameras, alongside forward facing and thermal, are deployed on in-service and measurement vehicles capturing incredibly comprehensive imagery of the track condition.

- Imagery and locational data is automatically transmitted and made available on the AIVR Platform for engineers to review, removing the requirement for boots on ballast.

- AIVR’s Machine Learning models automatically detect track components and defects, enabling quicker findings and decisions to be made where infrastructure issues are identified.

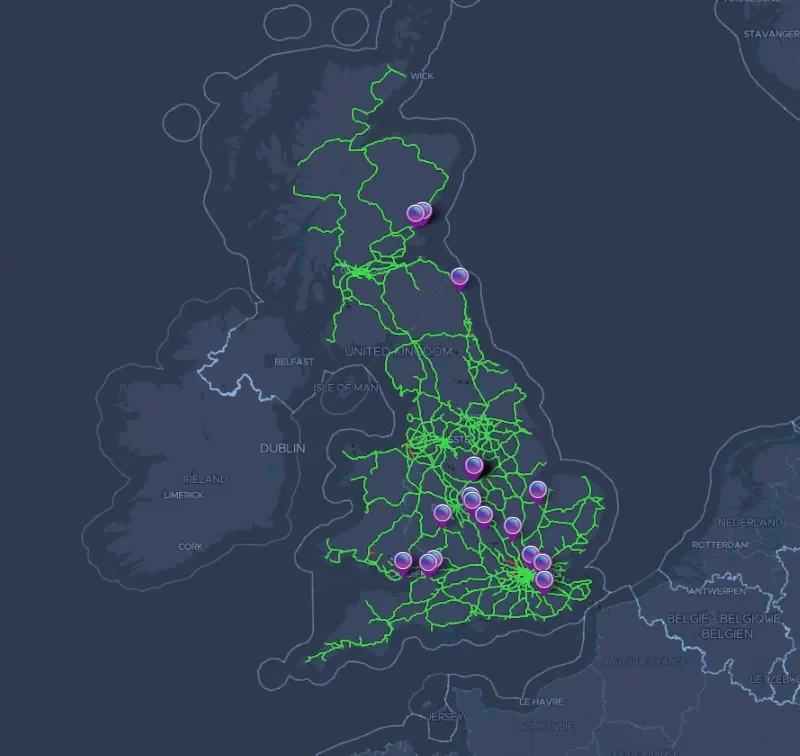

A number of measurement and in-service vehicles within the UK are outfitted with AIVR Focus devices. Each system is easily configurable to align with specific capture requirements, ensuring versatility and precision.

What our partners say about us

Share this Resource

Want to show your team the capabilities of AIVR Focus? Download the product PDF below and share it with important stakeholders.

Download