CASE STUDY

South Eastern Railway

Thermal and forward-facing cameras on in-service trains enabling predictive infrastructure maintenance

One Big Circle fitted advanced video sensors to in-service passenger trains operating across the South Eastern Railway network. The thermal and forward facing cameras installed on Class 707 and Class 375 trains have significantly improved remote railway monitoring and maintenance in the region. Partners in the project were Southeastern and Network rail.

The Challenge

Traditional railway infrastructure monitoring relied heavily on manual track inspections, periodic helicopter surveys, and handheld thermal imaging systems. This approach had several limitations: limited coverage across the 540-mile network, delayed fault detection, and safety risks for inspection teams working trackside.

With nearly 1,700 train services and up to 500,000 customer journeys daily, Southeastern needed a more efficient, safe, and data-driven approach to identify and address infrastructure issues before they caused service disruptions.

The Solution

One Big Circle worked with South Eastern Railway and Network Rail to design and install two complementary camera systems. Specifically engineered for the demanding rail environment, the thermal and visible forward facing cameras were fitted to the front of in-service Class 707 and Class 375 trains.

AIVR’s thermal and forward facing cameras installed on the Class 375.

AIVR’s thermal and forward facing cameras installed on the Class 707.

AIVR Thermal – Thermal Cameras

Thermal cameras capture thermographic imagery to identify overheating assets and potential failures before they occur. The thermal detection system automatically alerts users to temperature exceedances, providing precise network locations of high-risk thermal issues for proactive intervention. Lower-risk issues can be monitored over time to track developing conditions.

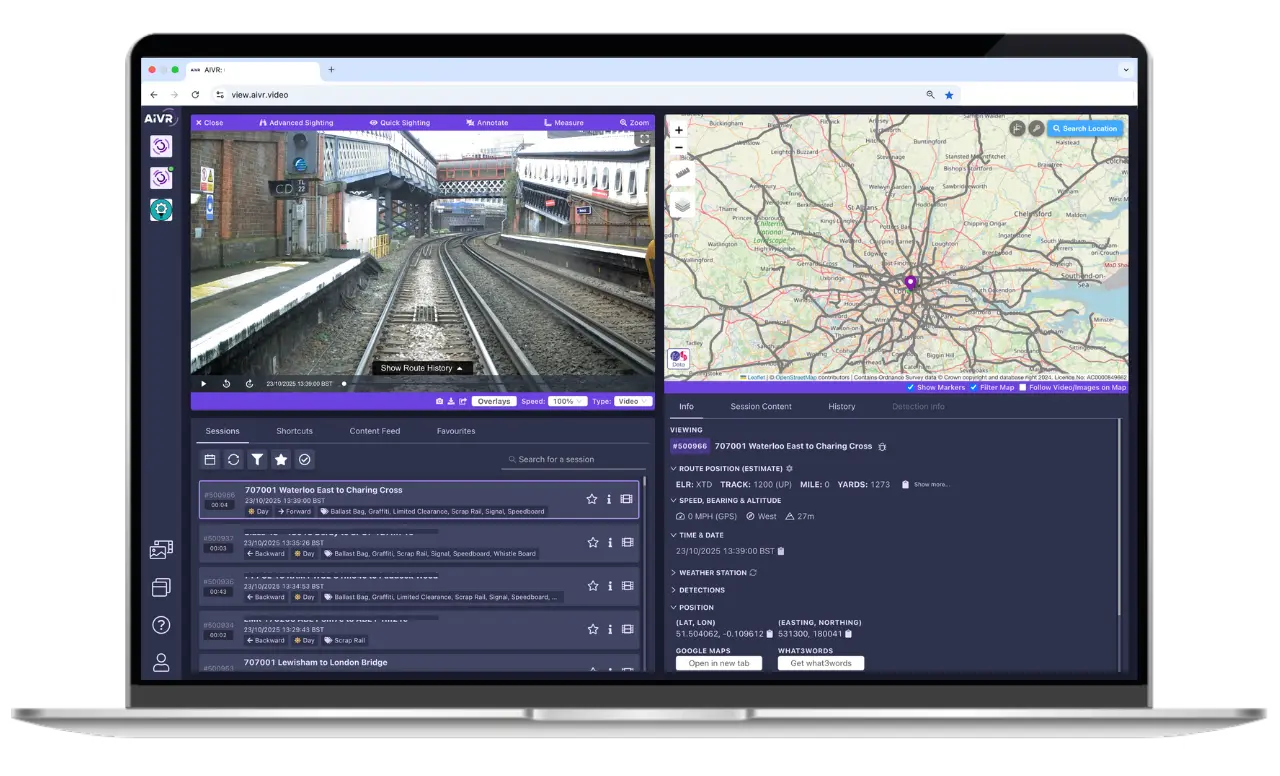

AIVR FFV – Forward Facing Video Cameras

Visible cameras record HD video of the track and lineside environment, providing contextual imagery for assessing detected thermal anomalies and enabling comprehensive infrastructure inspection and monitoring. Engineers use this footage to remotely conduct lineside inspections, assess track conditions, evaluate signal sighting, monitor vegetation management, identify scrap rail and materials, inspect drainage and earthworks, and review the condition of bridges, tunnels, and other structures. This capability transfers routine infrastructure monitoring from a physical site visit into a desktop review activity.

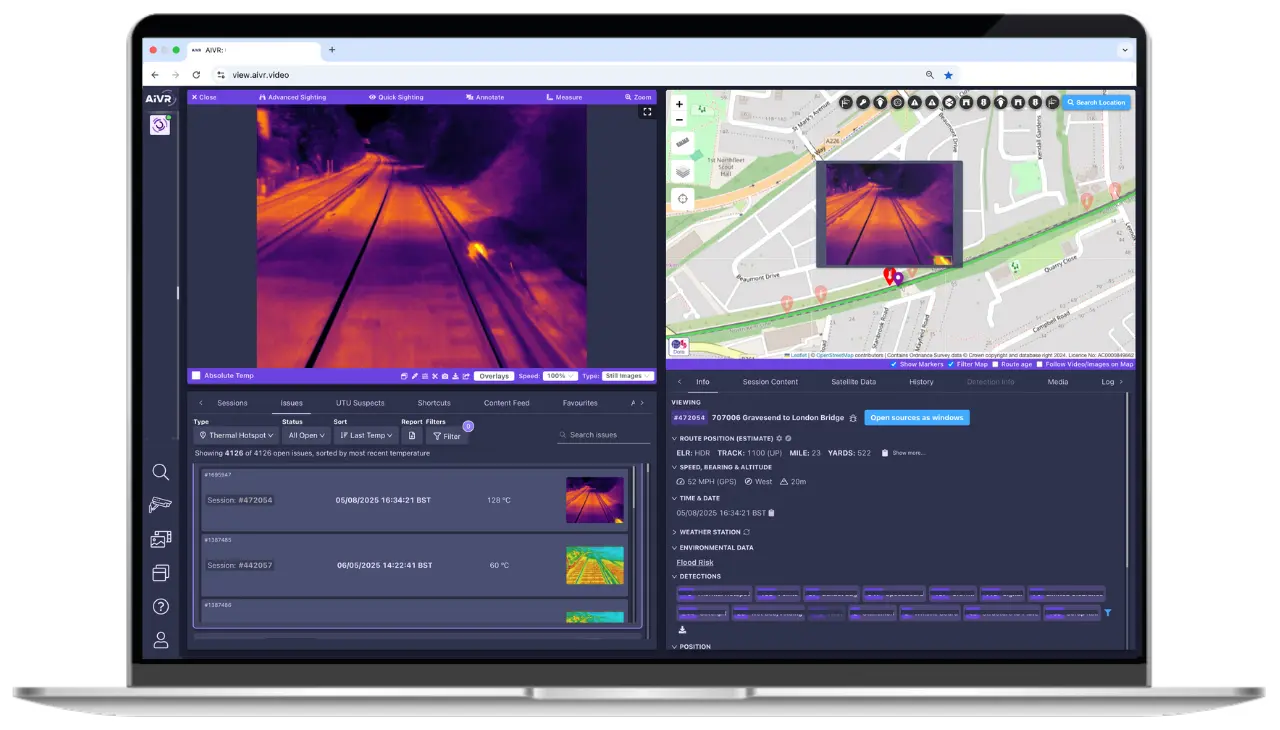

Thermal hotspot detected, with visible image for instant context.

The permanent deployment proved advantageous with enhanced coverage across the network, improved reliability of data capture, and consistent frequency of footage from regular service patterns. The installations included bespoke enclosures manufactured and calibrated with full factory testing before installation and commissioning on each train.

Automated Data Transmission

All captured data from One Big Circle’s AIVR systems is automatically transmitted via 4G/5G from the trains to AIVR’s cloud based platform in near-real time. The system employs dynamic demand management to ensure optimal bandwidth usage and transmission of only quality video, with intelligent data pooling between onboard devices to maximise efficiency.

Remote thermal inspection on the AIVR Platform.

The AIVR Platform

One Big Circle’s AIVR Platform is a secure, multi-award-winning system that enables remote inspection of rail infrastructure. Used widely across the UK network with over 11,000 end users, the platform hosts critical rail environment data from multiple sensor types including thermal, visible, overhead and high-resolution line-scanning imagery.

For Network Rail, all footage is made accessible online through the AIVR Platform, where users can perform comprehensive inspections from their laptops without needing to visit sites or conduct traditional ‘boots on ballast’ surveys.

Key Platform Capabilities Include:

- Automated hotspot detection: Machine learning algorithms automatically identify thermal anomalies and send email alerts to maintenance teams, categorising issues by risk levelSide by side video comparison: View thermal and visible footage simultaneously to assess the context and severity of detected issues

- Geographic mapping: All hotspots and assets are mapped to precise network locations with historical tracking to monitor condition evolution

- Digital Inspection tools: Annotation, measurement, asset location identification, and data export capabilities for maintenance planning

- AI-Powered asset detection: Machine learning identifies and maps lineside assets such as signals, scrap rail, and infrastructure components

- Automated data sharing: Seamless provision of data to Network rail and other stakeholders for coordinated maintenance activities

Remote infrastructure inspection on the AIVR Platform.

This comprehensive system has proven particularly effective at preventing conductor rail faults by predictively identifying components at risk of failure. Teams can act before potential fires on the track corridor, reducing both the safety risks and the significant reparative costs associated with thermal failures.

Implementation

Following a successful pilot programme last year, South Eastern Railway invested in expanding the technology across their fleet. The deployment includes:

- 12 Class 707 City Beam trains fitted with AIVR FFV and AIVR Thermal cameras covering London Metro Routes

- 20 Class 375 Electrostar trains equipped with forward-facing and thermal cameras for Main line routes across East Sussex and Kent

- 5 of the Class 375 trains fitted with additional AIVR Focus systems underneath the body of the train for remote inspection of the conductor rail and adhesion monitoring

The undercarriage cameras on the 5 Class 375 trains will monitor how slippery the track is as well as the condition of the ‘shoe’ and the conductor rail, which transfers the electricity to power the train. Assessments from these cameras will support further performance improvements, particularly during periods of challenging weather.

This integration has transformed passenger trains into mobile inspection platforms capable of providing real-time information on railway conditions across critical sections of the network, from London Metro routes to Main line services throughout Kent and East Sussex.

Key Benefits

Safety Improvements

Remote monitoring eliminates the need for engineers to work trackside for routine inspections, removing travel and safety risks associated with being on the railway. The technology enables proactive maintenance, reducing catastrophic failures through earlier fault detection.

Operational Efficiency

Remote monitoring eliminates the need for engineers to work trackside for routine inspections, removing travel and safety risks associated with being on the railway. The technology enables proactive maintenance, reducing catastrophic failures through earlier fault detection. During the pilot phase alone, 37 instances of overheating rail infrastructure were detected, and over 8,000 delay minutes were prevented.

Customer Experience

Early detection and preventive maintenance translate directly into fewer service disruptions, reduced delays, and improved reliability for the nearly 500,000 daily passengers using the network.

Predictive Maintenance

Machine learning algorithms track hotspot conditions over time, enabling maintenance teams to monitor developing issues and intervene before failures occur. This preventative approach is critical for reducing operational disruptions and maximising network performance.

Looking Forward

The success of this collaboration demonstrates the transformative potential of AI-powered monitoring technology in rail infrastructure management. As the system continues to capture data across the expanding fleet of 32 trains, machine learning algorithms will become increasingly sophisticated at detecting patterns and predicting maintenance needs.

The AIVR Focus systems installed on the Class 375 trains will provide valuable insights into track adhesion and conductor rail conditions, particularly during adverse weather conditions. This additional data layer will support further performance improvements and help maintenance teams understand and respond to seasonal challenges more effectively.

This partnership between One Big Circle, South Eastern Railway, and Network Rail represents a significant step forward in creating safer, more efficient, and more reliable railway operations through innovative technology and data-driven maintenance strategies.

Rail Minister, South Eastern Railway and One Big Circle visit at Hither Green station to mark the launch of South Eastern Railway.

One Big Circle’s Emily Kent showcasing AIVR to the Rail Minister.