CASE STUDY

KONUX Integration

Combining visual inspection with operational monitoring for predictive S&C maintenance

One Big Circle and KONUX integrated their technologies to provide Network Rail with a comprehensive solution for Switches and Crossings (S&C) maintenance. The collaboration combines One Big Circle’s high-definition visual inspection data with KONUX Switch’s advanced operational monitoring, delivering data-driven predictive maintenance capabilities for rail engineers. Partners in the project were Network Rail’s Sussex route and central Research and Development team.

The Challenge

Switches and Crossings are high-risk track assets that play a fundamental role in managing rail traffic flow. Due to significant dynamic forces and continuous use, S&C are prone to wear and deformation, requiring frequent inspections.

Traditional inspection methods had several limitations: S&C condition cannot always be determined by visual appearance alone but rather by operational behaviour when trains pass over, on-site workers operating within restrictive possession times often during night hours, and difficulty detecting faults before they become safety-critical.

Network Rail needed a data-driven approach combining visual inspection with operational monitoring to enable more efficient, predictive maintenance strategies.

The Solution

One Big Circle and KONUX worked with Network Rail to integrate their complementary technologies. The solution combines high-resolution visual data from AIVR with continuous operational monitoring from KONUX Switch IoT devices, providing engineers with a complete view of S&C health and condition.

AIVR – Rail Inspection Technology

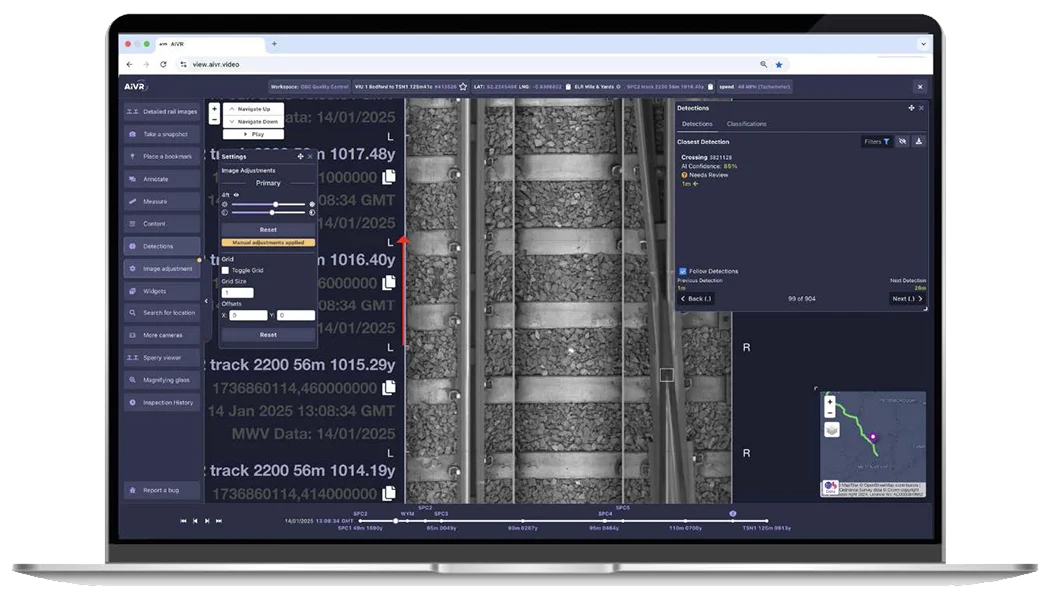

Line-scanning cameras deployed on maintenance vehicles such as VIU Class 153’s capture high-resolution imagery of track components. Machine learning and artificial intelligence automatically detect key components including joints, switches, and crossings, and proactively identify track defects. The data is automatically uploaded to the cloud-based AIVR Platform in near-real time, enabling engineers to access and review inspection data remotely.

Crossing detected by Machine Learning on the AIVR Platform.

The AIVR Platform provides analysis tools allowing users to annotate imagery, measure track components, zoom in for detailed inspections, review historical data to identify changes over time, and export data for reporting and decision-making.

Online Rail Inspection interface on the AIVR Platform.

KONUX Switch

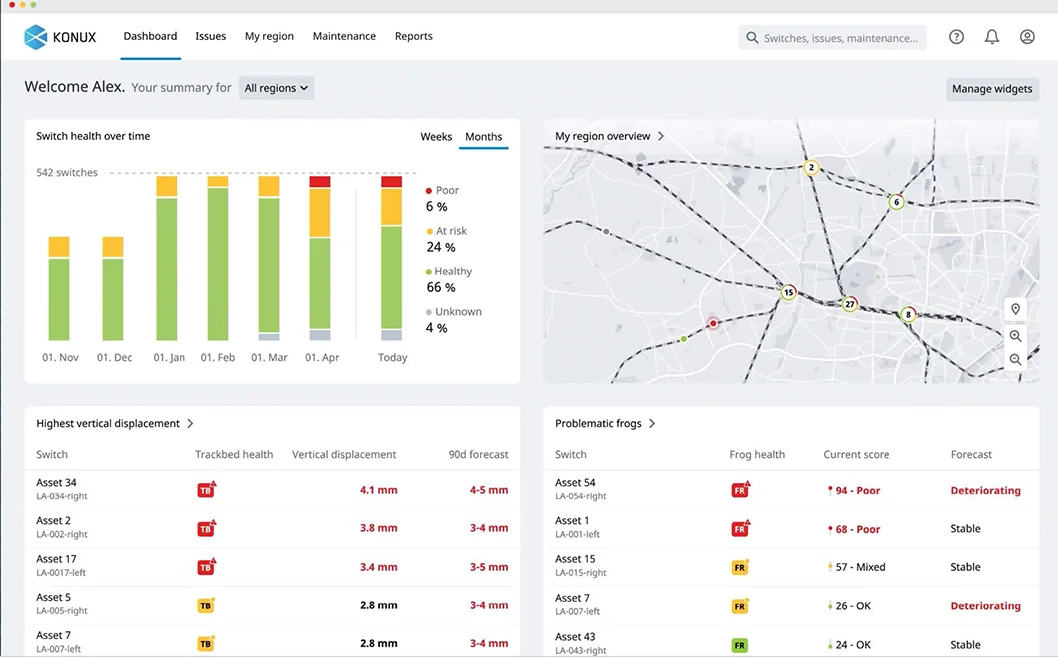

In-track IIoT devices continuously monitor and analyse the health of key switch components such as the trackbed, frog, and point machine. AI-driven analytics process the data to provide actionable insights, helping infrastructure managers anticipate failures, optimise maintenance timing, and improve network reliability.

KONUX Switch installed on the track.

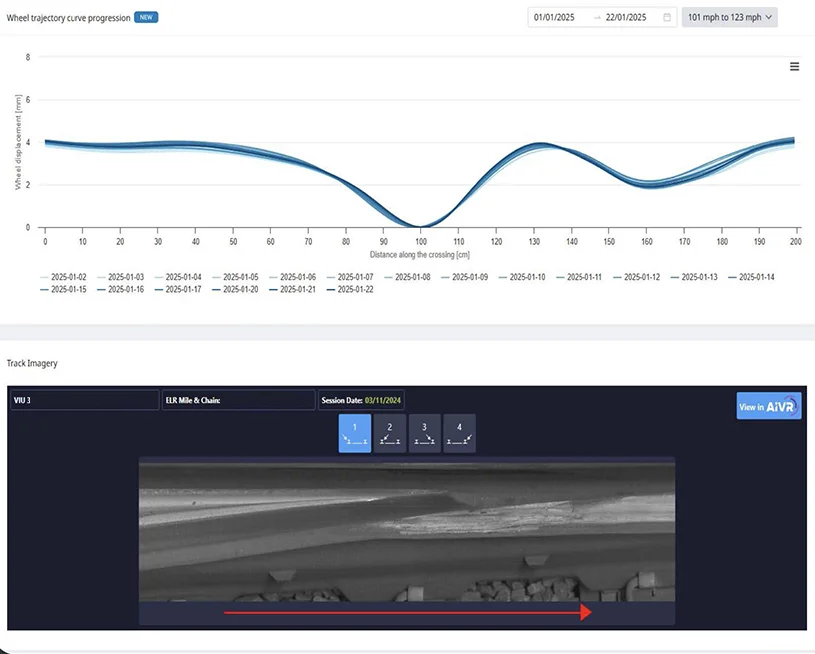

The system reconstructs vertical displacement of switches and crossings using Digital Twin models and intelligent data processing. The Wheel Trajectory Reconstruction (WTR) feature reconstructs the real movement of wheels over crossings, enabling precise identification of impact forces and degradation trends to predict wear and detect issues before they lead to failures.

Health metrics of switches displayed on KONUX Dashboard.

The Integration

In September 2024, KONUX and One Big Circle began working with Network Rail to develop, test, and assess the integrated solution. The integration provides engineers with detailed AIVR imagery of S&C being remotely monitored by KONUX Switch IoT devices.

Key Platform Capabilities Include:

- Embedded AIVR data: Line-scanning imagery displayed in KONUX Switch UI alongside health metrics

- Locational precision: Accurate asset identification enabling exact matching between visual and sensor data

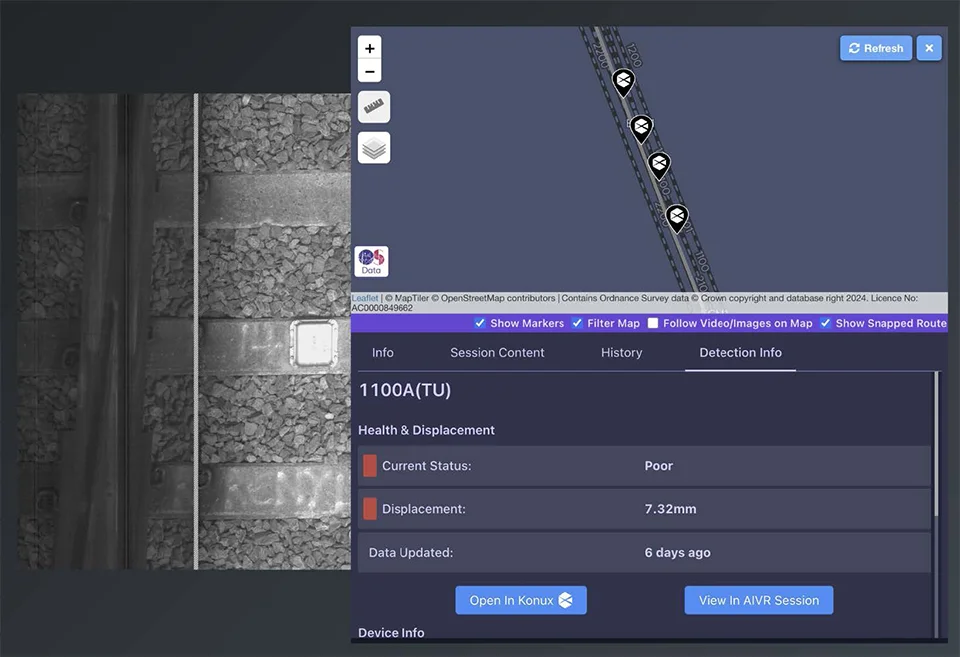

- KONUX data on AIVR: Asset health metrics displayed on AIVR Platform offering holistic view of S&C conditions

- WTR overlay: Wheel Trajectory Reconstruction progression curves displayed with recent AIVR imagery of railhead conditions

- Seamless navigation: Engineers can move between platforms to contextualise issues and plan maintenance effectively

KONUX Switch health metrics displayed on the AIVR Platform.

This comprehensive system has proven particularly effective at preventing conductor rail faults by predictively identifying components at risk of failure. Teams can act before potential fires on the track corridor, reducing both the safety risks and the significant reparative costs associated with thermal failures.

Implementation

The integration launched in September 2024 with Network Rail’s Sussex route and central R&D team. The deployment provides:

- Visual inspection data from AIVR Focus line-scanning cameras on VIU trains

- Continuous operational monitoring from KONUX Switch IoT devices installed on S&C

- Integrated data display in both KONUX Switch UI and AIVR Platform

- Real-time alerts and historical tracking for comprehensive condition monitoring

This combination enables engineers to understand both the physical condition and operational behaviour of S&C, providing complete context for maintenance decisions.

Wheel trajectory progression curve with visual AIVR imagery.

Key Benefits

Predictive Maintenance

The combination of visual inspection with continuous operational monitoring enables true predictive maintenance. Engineers can identify developing issues before they become critical, optimising intervention timing and reducing emergency repairs. Machine learning tracks patterns over time, enabling teams to monitor developing issues and intervene before failures occur.

Safety Improvements

Remote monitoring and inspection capabilities reduce the need for trackside work. Engineers can assess S&C condition, understand root causes, and scope maintenance requirements from safe locations. The ability to detect issues earlier prevents safety-critical failures.

Operational Efficiency

The integrated solution enables engineers to scope work remotely, reducing site visits and delivering right-first-time interventions. Automated detection directs attention to relevant areas, and comprehensive information supports faster, more confident decision-making. This streamlined workflow allows maintenance teams to manage assets more effectively.

Contextualised Decision Making

Engineers gain vital contextual information combining visual imagery with operational behaviour data. This enables understanding of root causes, remote work scoping, and reduced ‘boots on ballast’ whilst maintaining rigorous safety standards.

Award Winning Partnership

The partnership between One Big Circle, KONUX, and Network Rail won the Partnership category at the 2025 Railway Industry Association (RIA) RISE Awards, recognising excellence and achievement within the UK rail supply community.