18/12/2025

One Big Circle’s AIVR Cameras Help Prevent Train Delays on South Western Railway

AIVR technology has been installed on South Western Railway’s Class 450 ‘Hotshot’ train with advanced thermal and visible monitoring technology.

One Big Circle has been working in collaboration with South Western Railway (SWR), Network Rail, Angel Trains, Siemens, and dg8 Design on an innovative year-long trial that’s set to transform railway maintenance and passenger experience.

The AIVR (Automated Intelligent Video Review) system has been fitted to SWR’s Class 450 train number 450-056, aptly named ‘Hotshot’, to provide continuous, intelligent monitoring of track infrastructure across London, Surrey, Hampshire, Berkshire, and Dorset.

One Big Circle Systems Engineer George Handford with South Western Railway’s newly named ‘Hotshot’ train at the depot

How the AIVR Technology Works

AIVR Thermal – Thermal Imaging Camera

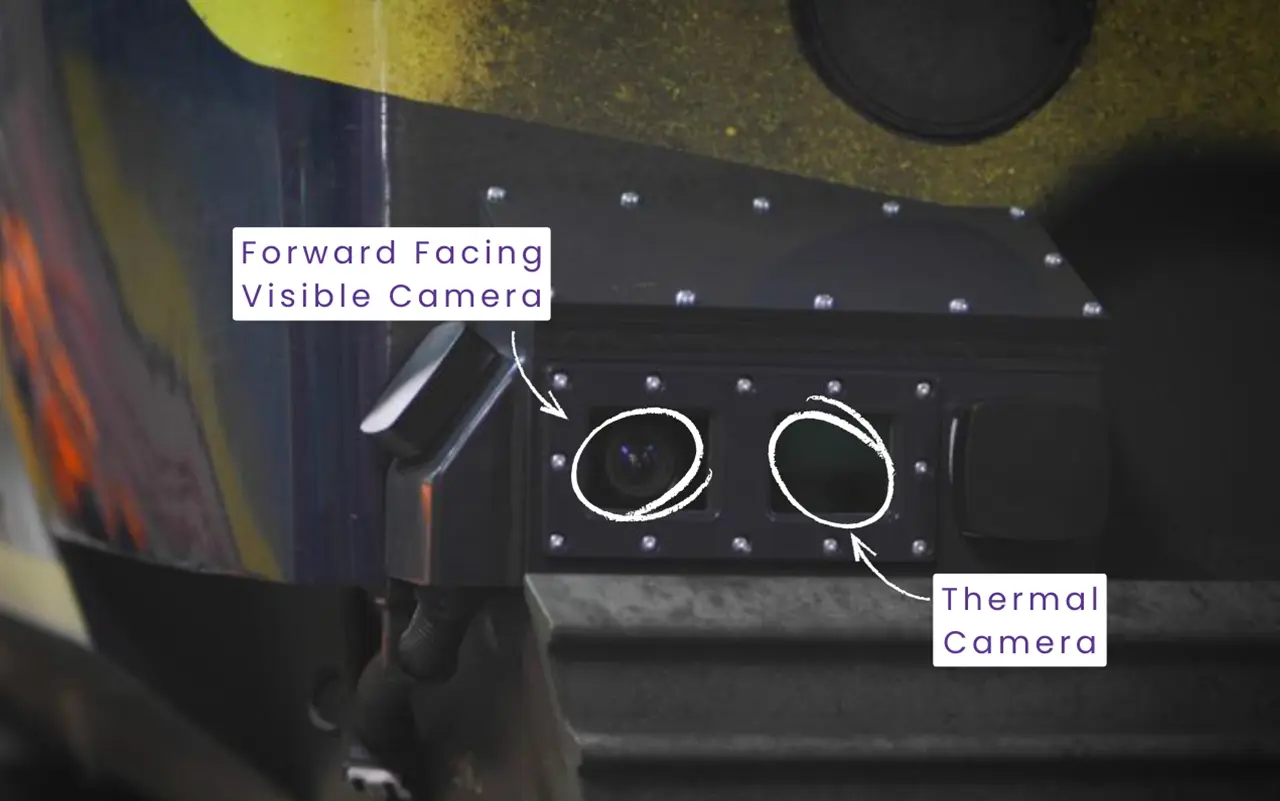

The award-winning thermal inspection technology captures thermographic imagery to identify overheating assets and potential electrical failures before they occur. Mounted at the front of the train, it detects electrical faults and unusual heat patterns along the track, enabling rapid response and predictive maintenance.

Forward-facing visible and thermal cameras mounted at the front of the Hotshot train

AIVR FFV – Visible Camera

HD cameras record detailed video of the track and lineside environment, providing essential contextual imagery for assessing detected thermal anomalies and enabling comprehensive infrastructure inspection of track, infrastructure, and asset conditions.

AIVR Shoe – Shoe Gear Monitoring

Two undercarriage cameras are positioned on both sides of the train to capture high-definition images of the interaction between the shoe and the third rail for remote inspection, monitoring the conductor rail power supply system.

AIVR Shoe camera positioned underneath the train to monitor the critical interaction between shoe gear and third rail

The AIVR Platform: Remote Inspection

All captured data is made available through our secure, multi-award-winning AIVR Platform – trusted by over 12,000 rail professionals across the UK network. Engineers can review data captured from SWR’s Hotshot train and compare video types simultaneously for a complete picture, conducting comprehensive inspections from their laptops without needing to attend site.

The AIVR Platform displaying side-by-side thermal and visible footage, enabling engineers to identify and assess infrastructure issues remotely

Key Platform Capabilities

- Side-by-side video comparison: View thermal, visible, and shoe footage simultaneously to assess the context and severity of detected issues.

- Automatic Alerts: The system provides email alerts for temperature exceedances, delivering precise network locations of high-risk thermal issues for proactive intervention. Lower-risk issues are monitored over time to track developing conditions.

- Geographic risk mapping: All hotspots and assets are mapped to precise network locations with categorised risk levels , enabling safe, prioritised repairs.

- Automated hotspot detection: Machine learning algorithms automatically identify thermal anomalies and categorise issues by risk level for faster response.

- Digital inspection tools: Measure distances, annotate footage, create signal sighting reports, review safe cess, search locations, view route history, and export data – all remotely.

- AI-powered asset detection: Machine learning models identify and map lineside assets such as signals, scrap rail, infrastructure components and more, alongside their conditions

- Automated data sharing: Seamless provision of data to Network Rail and other stakeholders for coordinated maintenance activities.

This capability fundamentally transforms routine infrastructure monitoring from a physical site visit into an effective desktop review activity, delivering immediate safety, efficiency, and cost improvements.

Proven Results

During an earlier trial, the AIVR cameras identified a fault near Ashtead, Surrey, which was rectified within 48 hours with zero impact on passenger journeys. Network Rail reports that a similar previous incident caused 2,500 minutes of delays.

On average, the types of faults the system can detect typically cause around 200 minutes of delays. In more severe cases, conductor rail issues have resulted in over 2,000 minutes of disruption.

This comprehensive system has proven particularly effective at preventing conductor rail faults by predictively identifying components at risk of failure. Teams can act before potential fires on the track corridor, reducing both the safety risks and the significant reparative costs associated with thermal failures.

Engineering teams fitting AIVR camera systems to Class 450 train number 450056 during the installation process

Cross-industry Collaboration

Building on industry progress in neighbouring regions and the drive for innovation within the region, this project represents the first time AI-powered monitoring has been deployed across the SWR network. The initiative has been designed, managed, and funded by Angel Trains, with One Big Circle providing the core AIVR technology including the hardware and software, enabling secure online access for remote review.

Feedback

Rail Minister, Lord Hendy:

“This Government is fundamentally reforming how our railways are run – creating a network that works better for the people and freight using it.

The cutting-edge technology that the integrated South Western Railway is trialling is key to achieving this and will serve as an example of the kinds of smart investments publicly owned rail companies can implement to improve services for passengers.

Upgrades like this will prevent disruption and reduce delays – supporting growth, jobs and homes as part of the Government’s plan to deliver an efficient and reliable railway.”

Neil Drury, Engineering and Infrastructure Director for South Western Railway:

“Much like our famous ‘Flying Banana’ train which helps monitor the tracks, you can now look out for Hotshot. We hope this innovative collaboration between SWR, Network Rail, Angel Trains and our other partners will identify potential infrastructure issues before they escalate, helping to reduce disruption on the network and keep our customers moving.”

Barry Fox, Head of Product Management at Angel Trains:

“We’re proud to be supporting the introduction of this technology on passenger trains. Continuous monitoring of the infrastructure offers real value in helping deliver a more reliable railway for passengers. This has been made possible by working closely with our customers and suppliers to deliver a fully integrated solution.”

Emily Kent, Co-Founder at One Big Circle:

“The One Big Circle team is delighted to see our AIVR technology supporting this fantastic collaboration. By capturing and combining forward-facing, thermal, and under-train shoe cameras and applying AI we are able to deliver actionable imagery and data for engineers. This digital review capability provides the intelligence needed to monitor infrastructure, identify potential issues early, and ultimately help keep the railway safe, efficient, and resilient.”

The Future of Railway Monitoring

If the year-long trial proves successful, the AIVR technology could be rolled out across the additional trains in the SWR fleet, further expanding network coverage and reliability.

By combining thermal imaging with machine learning and AI-powered models, One Big Circle is helping to create a safer, more efficient, and more reliable railway network – delivering tangible benefits for passengers, operators, and maintenance teams alike.