23/09/2025

One Big Circle Strengthens Rail Monitoring With Vista Geometry Systems

One Big Circle has expanded its advanced rail monitoring suite by adding Vista Geometry Systems, introducing the powerful AIVR Geometry to its portfolio. This upgrade delivers enhanced, automated track geometry analysis, empowering rail operators with critical insights for network-wide safety and asset management.

“After a number of years of working closely with the experts at Vista Instrumentation we’re excited to be bringing this world-renowned geometry capability more firmly into our ecosystem of rail technology solutions,” said Emily Kent, Co-Founder. “This enables us to provide an even more complete view of the railway environment — from visual intelligence to precise measurement data — all working together to support a smarter, safer railway.”

“One Big Circle has consistently demonstrated its commitment to innovation and service,” said Edwin Reeves, Managing Director at Vista Instrumentation. “In addition they have a very strong engineering staff and we’re confident they are the right people to bring Vista Geometry to a broader audience with the technical expertise and industry understanding required.“

What Does Track Geometry Measurement Do – and Why is it Critical?

Track geometry measurement systems are fundamental to the railway’s safety, reliability, and performance. These systems rigorously evaluate how well the physical rails are aligned, spaced, and levelled across thousands of miles of railway infrastructure. Track geometry measurement precisely monitors essential parameters such as gauge (distance between rails), alignment (straightness and smoothness), curvature, crosslevel (difference in rail height), warp, twist, and vertical/horizontal profiles. By measuring these characteristics, engineers can detect subtle deviations or gradual wear before they become hazards.

Why is this Important?

Track-related derailments are often caused by issues that geometry measurement can catch early – such as broken rails, cracked fasteners, and thermal misalignment. If left undetected, these faults can compromise train stability, increase the risk of component failure, and potentially lead to accidents. Consistent, high-precision measurement supports targeted maintenance, ensuring that emerging problems are addressed before they pose issues to safety or service reliability.

Track Geometry Measurement Systems (TGMS) are specialised technologies designed to assess the alignment and condition of railway tracks, providing essential data for ongoing safe rail operations and comfortable customer journeys.

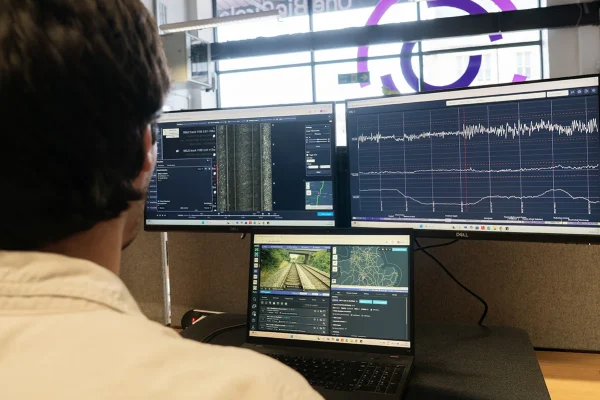

Vista installation on the Class 153 VIU.

The AIVR Geometry Edge – Unattended Operation and Online Data Review

Unlike traditional systems that require staff on-site or onboard for data collection, AIVR Geometry utilises advanced laser technology installed onboard maintenance trains such as the VIU Class 153s. This allows for automated, highly accurate geometry measurements as these trains operate across the network – all without the need for staff to be present trackside or onboard during data collection. This brings together several major advantages:

Increased Safety and Efficiency

Instead of traveling to hazardous trackside environments or spending hours collecting data, staff can now securely and efficiently review all geometry video, and imagery data online – directly from the AIVR Platform. This shift not only reduces risk, but also enables engineers to cover much greater areas in less time, enhancing productivity and responsiveness.

No Track Closures Required

Inspections are carried out during normal service, maximising network availability and minimising operational disruptions.

Laser-Based, Non-Contact Measurement

Ensures high precision and repeatability, even at varying speeds or in challenging conditions.

Line-scanning imagery, forward facing video and track geometry displayed on the AIVR Platform.

Integrating Geometry with Rail Imagery

What also sets AIVR Geometry apart from traditional track geometry systems, is that it doesn’t just collect geometry measurements in isolation. Its data is combined with synchronised line-scanning imagery, forward-facing and thermal video imagery, and other meta data – all uploaded to the online AIVR Platform for review. This gives engineers a comprehensive digital twin of the railway, enabling them to review geometry data and correlated visual evidence for each section of track, and instantly prioritise areas showing signs of risk, such as dipped joints or broken fishplates, and then direct maintenance response efficiently.

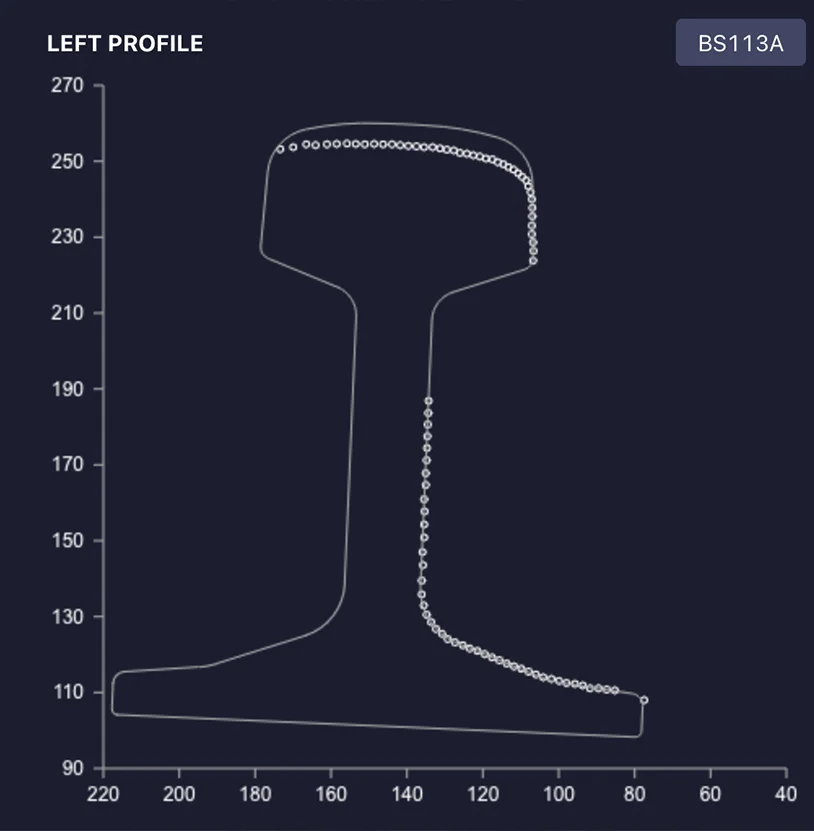

AIVR Geometry Rail Profile Capture.

Rail Profile capture

A further capability delivered by AIVR Geometry is the capture of Rail Profile data. This is provided by the same AIVR Geometry unit with no additional sensors, hardware or gauging requirements and delivers a ‘half’ rail profile data stream in parallel with the Geometry data stream.

The system generates a precise digital shape of each rail it inspects which can be automatically processed by AIVR and then other systems to enable the rail profile to be matched and allowing engineers to remotely assess where rails are starting to wear or degrade, and to make informed, timely decisions about maintenance or replacement, all without needing to step a foot onsite. Crucially, it also identifies the most likely match of rail fitted across the network. Given the UK’s ageing infrastructure, with over 20,000 miles of track and a diverse mix of rail types, this capability allows Network Rail and other infrastructure operators to accurately map out areas of older and newer infrastructure, target resources, and plan renewals with greater efficiency.

By enabling engineers to both monitor rail profile and preview potential rail types remotely, AIVR Geometry supports smarter, evidence-based asset management, helping teams to understand what’s in the ground, prioritise where renewal makes sense, and identify areas where legacy materials might present future risks, all without needing to send staff on site except when absolutely necessary.

Data Sharing and Integrations

As with all AIVR products the captured Geometry and Profile data from AIVR Geometry is available to visualise within the AIVR dashboard after passing through our automated processing pipeline but crucially it is also provided as a machine readable data feed over a secure connection from the AIVR Cloud to the preferred Cloud provider of the infrastructure owner. This enables them to also process the data through their own standards based systems and / or enable other suppliers to provide further analysis and interpretation of the data for gaining further insight or combining with their own data feeds. To further aid this AIVR provides a suite of integrations to enable simple connection to and from these systems to ensure the end engineer gets to the data and analysis as quickly as they possibly can.

Want to see AIVR Geometry in action? Get in touch with our team to book a demonstration.