26/08/2025

Collecting a Range of Data Across the UK Rail Network

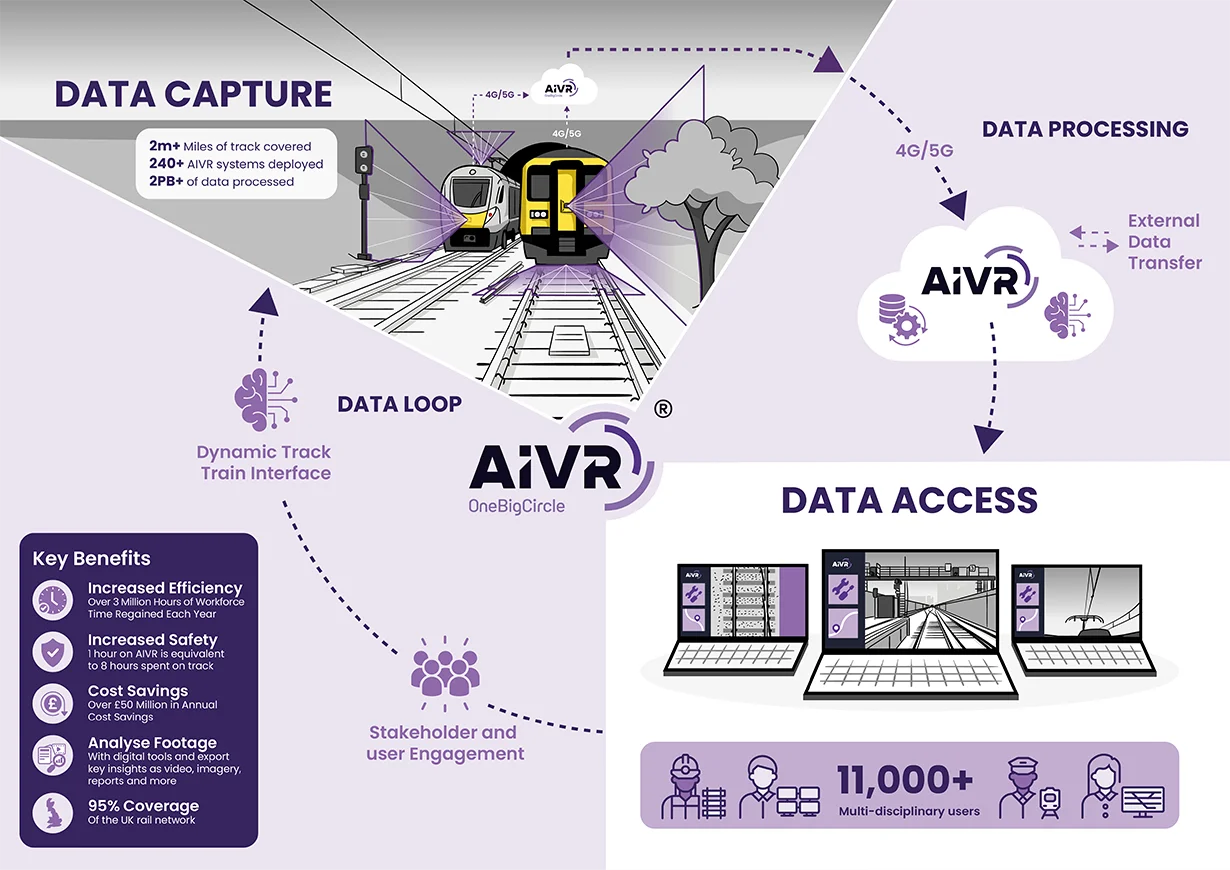

One Big Circle’s AIVR (Automated Intelligent Video Review) technology provides nationwide data capture for the UK’s railways – delivering the imagery and intelligence needed to help keep the network safe, efficient, and future‑ready.

Covering over 95% of the UK rail network and actively supporting more than 11,000 rail professionals, AIVR delivers safer, smarter, and data‑driven solutions for infrastructure monitoring and maintenance.

This multi‑award‑winning system equips in‑service and maintenance trains with lightweight, deployable, or bespoke, and fully integrated cameras to capture:

- Forward Facing Video – for monitoring track and lineside conditions

- Structural Inspection Video – for detailed review of bridges, platforms, and assets

- Thermal Imagery – identifying hotspots for predictive maintenance

- Overhead Line Footage – monitoring electrification assets

- High‑Definition Line‑Scanning Imagery – capturing fine detail of the rail such as switches, crossings, and componentry

- … Plus more

Each type of data capture supports a wide range of users – from signal sighters and planners, to maintenance teams, asset engineers, and project managers – providing a targeted intelligence to improve safety, reduce costs, and reduce the need for on-foot inspections.

Built In-House, Designed for the Network

AIVR systems are built and installed by our specialist in-house engineering team, and by working closely and collaboratively with key industry partners. With more than 240 devices deployed across passenger fleets and maintenance vehicles, AIVR now captures inspection data covering almost the entire UK rail network.

All the data capture methods operate automatically and transmit captured data to the AIVR Platform via secure 4G/5G connectivity – removing the need for manual data offloads and eliminating delay between capture and review.

This seamless process is pivotal in reducing on-site track inspections; offering a cost-effective solution for railway monitoring.

Flexible Data Capture Options

Because the UK rail network is diverse, AIVR offers different types of installation to suit different operational needs:

Deployable Installs – Portable & Versatile

- AIVR Go – Our first commercial product – a phone-sized device that mounts internally on the windscreens of almost any rolling stock using a suction mount. Fully portable, it can be quickly transferred between trains and routes in a single day, giving exceptional flexibility to target priority areas.

- AIVR TLC (Tail Lamp Camera) – Also known as the “T-Box”, this robust, stringently-tested housing mounts externally on the tail lamp bracket of any compatible locomotive and can carry forward-facing, thermal, or combined camera systems. Its rugged design allows quick redeployment between vehicles to optimise coverage.

Bespoke Installs – Tailored & Fully Autonomous

Working with train operators, ROSCOs and manufacturers, we provide permanent installations tailored to specific fleets. These can include:

- Forward facing cameras

- Thermal Cameras

- Line-Scanning Cameras

- Overhead Line Cameras

- Laser-based Track Geometry Systems for detailed measurement data

These systems are fully autonomous – operating automatically whenever power is applied, without the need for operator input or recharging.

Example: Class 707 Fleet

In partnership with Southeastern and Network Rail, several Class 707’s were fitted with AIVR Forward Facing and Thermal cameras for continuous in-service monitoring during standard service runs.

Example: Class 153 Visual Inspection Units (VIUs)

Working with Network Rail, Porterbrook, and others, formed Class 153 units have been converted into Visual Inspection Units, equipped with Forward Facing, Thermal, Line-scanning and Structural Inspection cameras, and Track Geometry Systems. These units aid structural inspection, switch and crossing monitoring, and thermal analysis.

Integrated Systems – Enhancing Existing Assets

AIVR can also integrate directly with existing onboard cameras and systems – including specialist systems like the Network Rail NMT (New Measurement Train), collecting forward facing and overhead line footage.

The AIVR Connect devices work independently of train communication systems, fitting neatly into existing cabinets or housings. Data is automatically uploaded from the different device types using 4G/5G, transforming existing analogue fleets into data hubs for rail analysis.

End-to-End Remote Inspection – From Trackside to Desktop

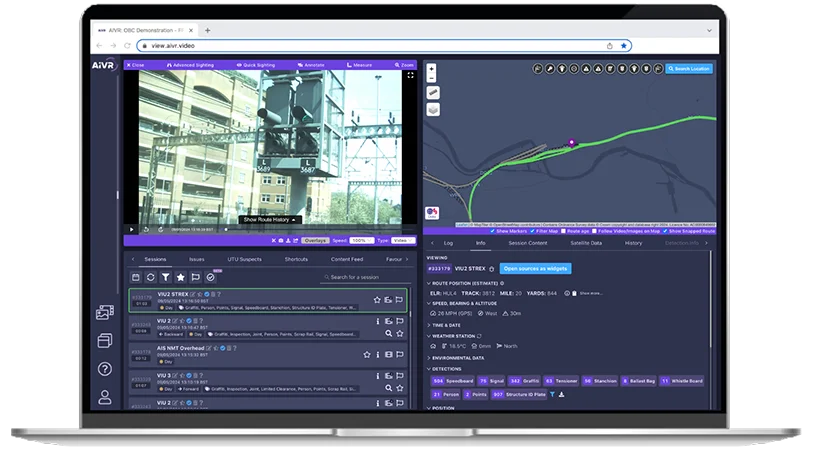

The AIVR Platform gives more than 11,000 rail professionals across infrastructure owners, contractors, train operators, and the wider supply chain secure online access to inspection imagery.

Users can:

- Review and analyse video data

- Access a suite of digital tools such as annotation, measurement, sighting and more

- Compare rail environment over time

- Export data, report, and share findings with colleagues

Every hour reviewed on the platform saves up to 8 hours of traditional site inspection time – reducing safety risks, environmental impact, and operational costs.

Bringing External Feeds into One Platform

Beyond onboard systems, AIVR can also ingest external data and third-party data feeds, such as drones, inspection data, contractor-supplied imagery or photos, remote condition monitoring sensors and other forms of data.

By aggregating these sources with AIVR’s own captured data, the AIVR Platform creates a unified inspection environment, allowing cross-referencing from multiple sources for a comprehensive understanding of assets.

Building a Smarter, Safer Network

By combining advanced data capture, secure cloud access, and powerful AI analysis, AIVR is helping the rail industry move towards fewer site visits, earlier fault detection, faster maintenance response and to proactive practices.

Trusted across the industry, AIVR empowers engineers, planners, and maintenance teams to keep Britain’s railway moving safely, efficiently, and sustainably – building a smarter and more resilient railway network.

Looking to collect your own data? If you’re exploring ways to capture, centralise, and get more value from your inspection data – whether onboard your own fleet, portable systems, or by integrating existing feeds – talk to our team.