Ballast

What is it

Railway ballast is a layer of coarse, hard, angular aggregate (typically 30-50 mm crushed stone such as granite) placed beneath, between and around sleepers to form the trackbed. It creates a free-draining foundation of interlocked stones between the sleeper and the underlying formation (sub-ballast).

Why it matters

Ballast provides several critical functions: it distributes wheel loads from rail and sleeper into the subgrade, stabilises track laterally and vertically, helps maintain track geometry, controls vegetation and offers drainage to prevent water accumulation and frost damage. It also attenuates vibration and noise, improving ride quality and reducing dynamic stresses on the formation.

Primary disadvantages comprise gradual fouling by fine particles, diminished angularity, and plastic deformation, all of which contribute to increased maintenance requirements such as tamping, stoneblowing (using pressurized air to inject measured amounts of small ballast stones under track sleepers to correct track level and alignment), and ballast renewal. Ballasted track has higher rates of routine maintenance and geometry degradation than well-designed slab track, and ballast flight (flying ballast stones) can be an issue at very high speeds or under intense aerodynamic loading.

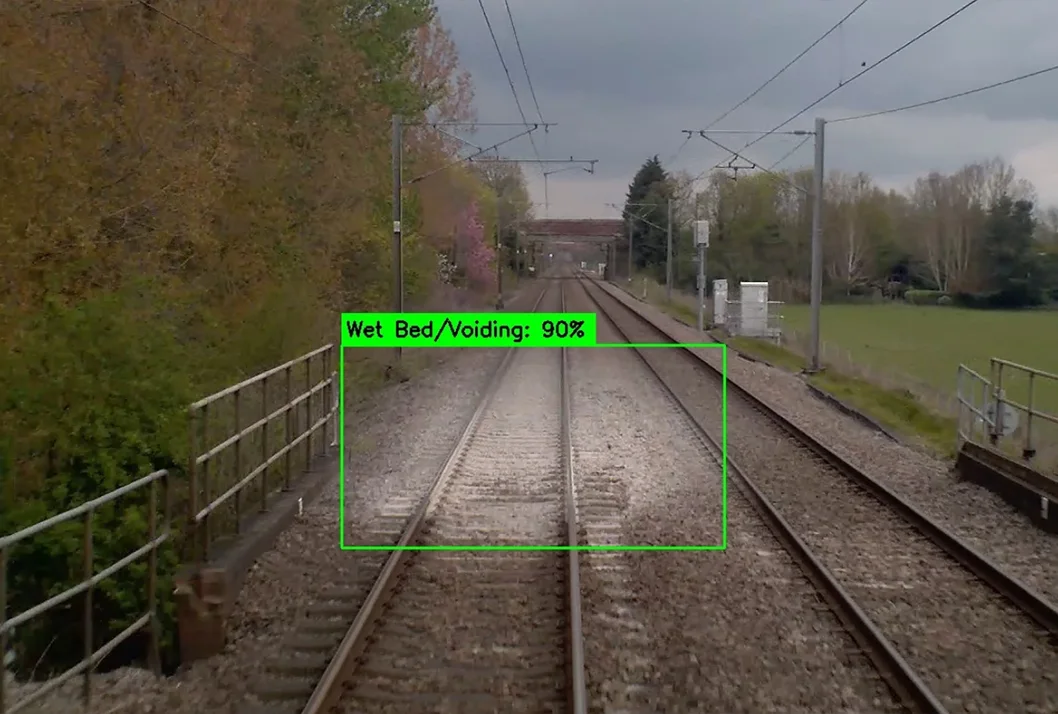

Traditional ballast condition monitoring methods typically involved walking the line to conduct BVIs. Automated, remote monitoring is now becoming common, using systems such as AIVR Ballast Condition Monitoring.

Wet Bed automatically captured and detected by AIVR.

Where it is used

Ballast is generally best suited to open-route conventional and mixed-traffic lines, secondary routes and locations where ease of maintenance, drainage and adaptability outweigh the lifecycle advantages of slab systems.

Ballasted track remains the dominant solution on conventional railways in the UK, where granite or other durable stone ballast is standard across most Network Rail routes. Across Europe, ballasted track is still widely used (for example in Austria and much of the mainline networks of Germany, France and others), with slab track reserved more for high-speed lines, tunnels and major structures.

Globally, extensive ballast use continues in North America, much of Africa, Australia, India and many conventional lines in East Asia, while countries such as China, Japan, South Korea, Germany and Spain employ significant lengths of ballastless track on high-speed and urban routes.

When it is used

The term “ballast” in railway use originated in the UK, linked to ship’s ballast gravel landed at ports such as Tyneside and Portmadog and adopted for early permanent way in the 19th century. Early railways commonly used locally available gravel or mine waste as ballast; the move to crushed hard stone improved performance as train loads and speeds increased.

Over the last few decades, use of slab track has grown on new-build high-speed corridors and metros, but worldwide route-kilometres of ballasted track remain far larger, and new conventional lines still predominantly adopt ballast. The strategic trend in many countries is a mixed estate: incremental renewal of existing ballasted lines alongside targeted slab-track deployment where justified by speed, access constraints or life-cycle cost.

How it works

Ballast works through interlock and confinement: the angular stones compact under load to form a stable skeleton that grips sleeper ends and resists lateral and vertical movement under traffic and temperature-related effects. Loads transfer from rail to sleeper, through the sleeper-ballast contact area and down into the subgrade over an enlarged footprint, reducing stress concentrations.

The designed ballast profile and depth, combined with its permeability, channel water away from the sleeper soffit and formation, limiting pore pressure and degradation. Maintenance activities such as tamping restore geometry by rearranging and recompacting ballast, but repeated cycles gradually break down the aggregate, eventually necessitating ballast cleaning or renewal to recover performance.