CASE STUDY

Class 153 Visual Inspection Units

Converting former passenger trains into autonomous inspection units

This project converted a fleet of former passenger trains into AI-powered mobile inspection platforms. The reequipped Class 153 trains have transformed railway infrastructure monitoring, becoming hi-tech Visual Inspection Units (VIUs). The project rolled out in 2023 and was a collaboration between One Big Circle and partners including Network Rail and Porterbrook.

The Challenge

Across Britain’s 20,000-mile rail network, the highest-risk assets in engineering terms are Switches and Crossings (S&C). These critical components are particularly vulnerable to wear and deformation caused by train movements. They require frequent inspections, up to weekly in high-use areas.

Traditional inspection methods presented significant challenges:

- Safety risks: Track workers were required on-site, often at night and with limited lighting. This exposed them to potential hazards.

- Service disruption: Manual Inspections required track possessions, disrupting passenger and freight services.

- Time constraints: Increasingly tight possession windows made the task of completing inspections challenging.

- Resource intensive: Physical inspections required significant personnel deployment across the extensive network.

Following a series of serious safety incidents, Network Rail urgently required safer and more efficient track inspection methods that would reduce trackside working.

The Solution

One Big Circle, alongside Network Rail, Porterbrook, Machines with Vision, and other industry partners, developed an innovative solution by converting redundant Class 153 passenger trains into sophisticated Visual Inspection Units. These autonomous inspection trains operate at line speeds up to 70 mph, capturing comprehensive data without requiring track possessions or putting workers at risk.

Class 153 passenger train pre transformation. Photo credit: Hugh Llewelyn.

Class 153 Visual Inspection Unit post transformation. Photo credit: Alan Padley.

Comprehensive Technology Suite

Each VIU is equipped with One Big Circle’s AIVR (Automated Intelligent Video Review) technology platform, featuring multiple advanced monitoring systems:

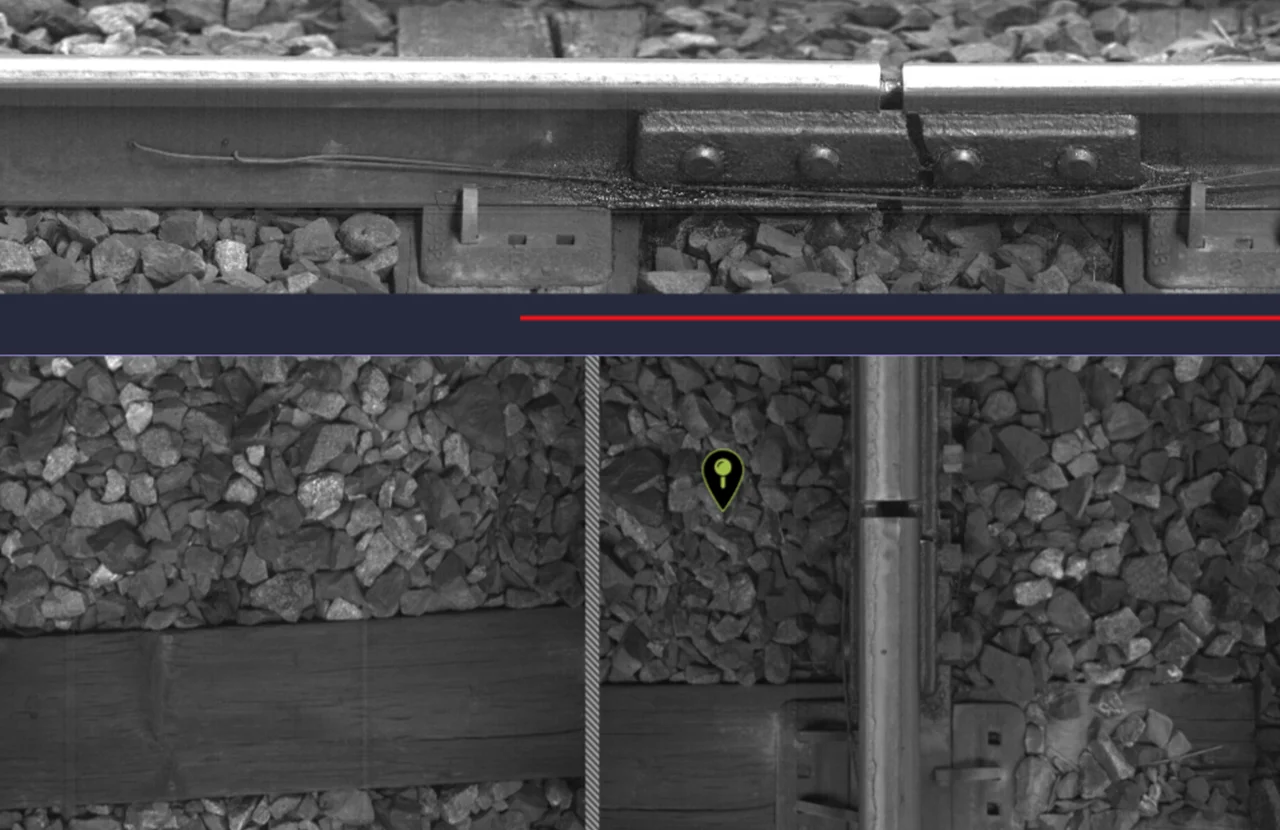

AIVR Focus – Line-Scanning Cameras

Provides high-definition imagery of track components; the system utilises machine learning to automatically identify and map critical track components including joints, switches, crossings, adjustment switches, welds, and railhead defects. This automated detection capability ensures comprehensive coverage and consistent identification of potential issues across the network.

Broken joint captured and detected by AIVR.

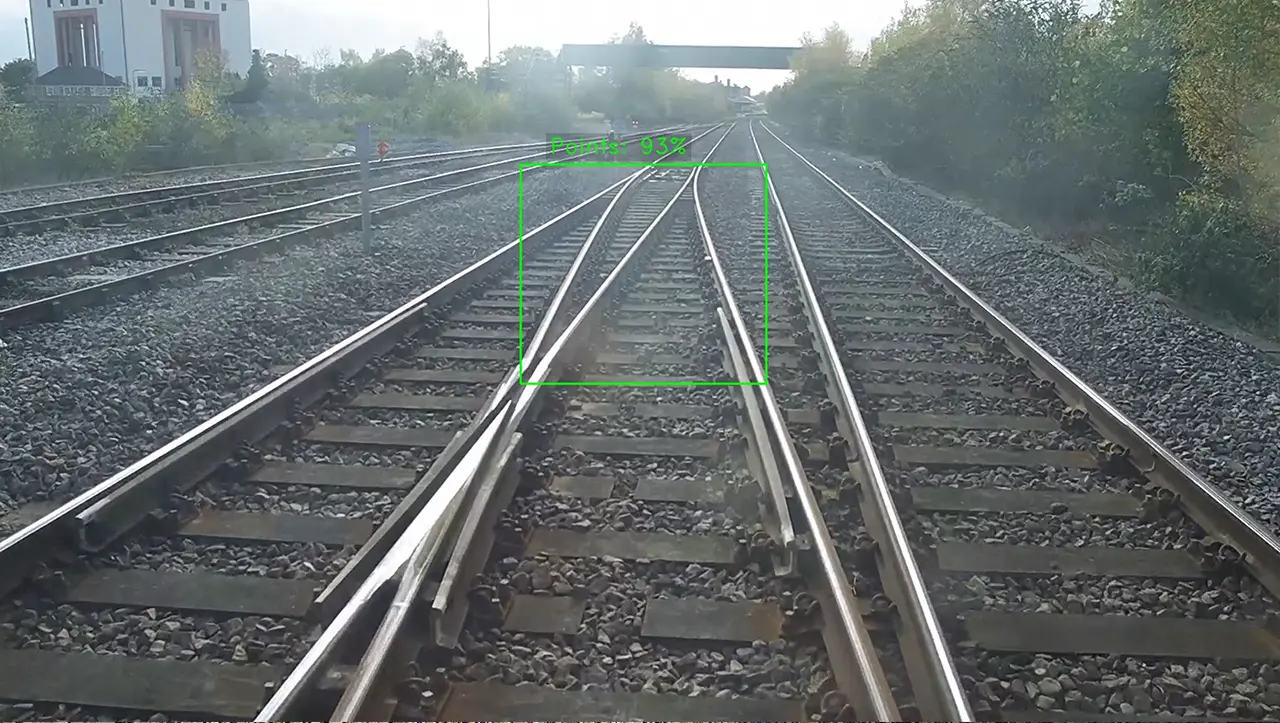

AIVR FFV – Forward Facing Video Cameras

Captures HD video of the track and lineside environment for comprehensive infrastructure inspection. Engineers used this footage to remotely assess track conditions, evaluate signal sighting, monitor vegetation, identify scrap rail, inspect drainage and earthworks, and review bridges, tunnels, and other structures.

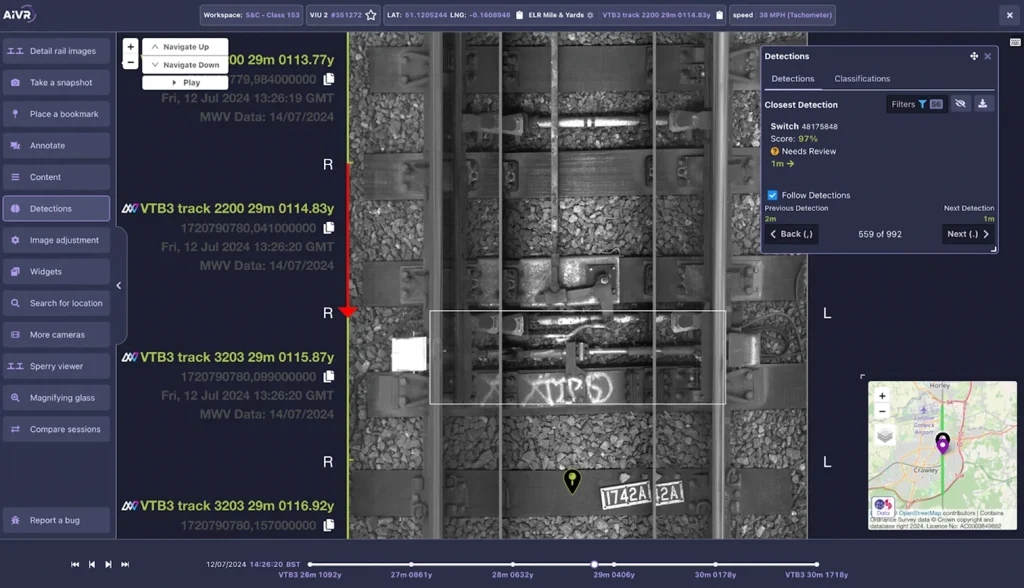

Point captured and detected by AIVR.

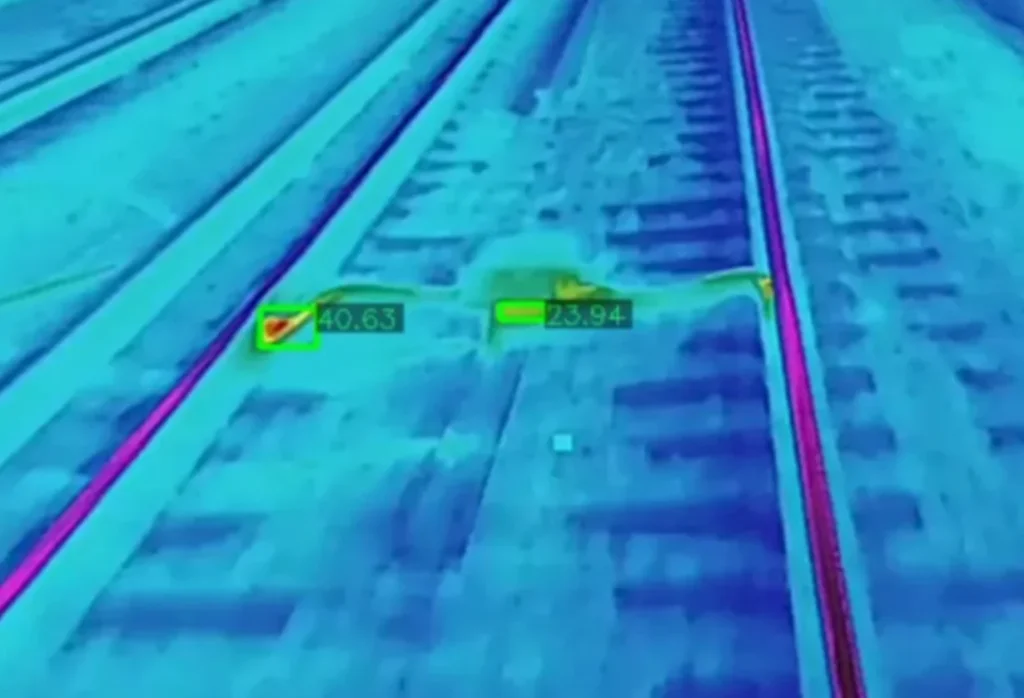

AIVR Thermal – Thermal Cameras

Monitors the rail network for thermal anomalies and hotspots that could indicate developing faults in conductor rails and other critical electrical infrastructure, enabling predictive maintenance interventions.

Thermal hotspots captured and detected by AIVR.

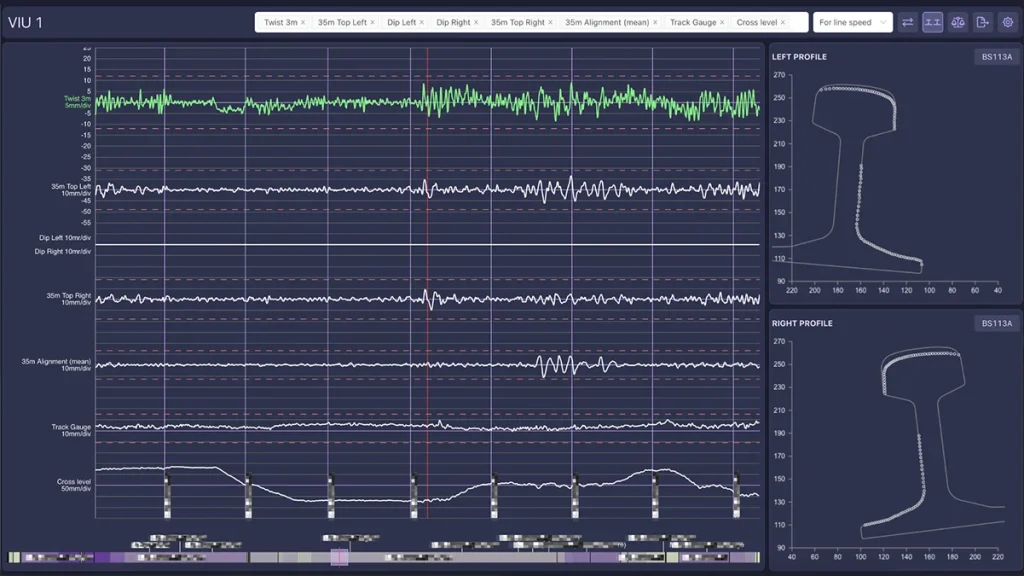

AIVR UGMS – Laser-Based Track Geometry

Records comprehensive track geometry data including gauge, twist, alignment, level, dipped joints and dip angles, alongside detailed rail profile data for wear monitoring and predictive maintenance planning, enabling early intervention before critical thresholds are reached.

Track geometry and rail profile data available on the AIVR Platform.

AIVR STREX – Structural Examination Cameras

Provides visual data of the wider rail corridor and structures, offering enhanced imagery for structural inspections, lineside vegetation monitoring, access points assessment, OLE inspection, and lineside equipment evaluation across multiple operational disciplines.

Structure Inspection footage captured by AIVR.

The AIVR Platform

All captured data is transferred seamlessly to One Big Circle’s cloud based AIVR Platform via 4G/5G, where it becomes available to Network Rail engineers in rapid time. The platform integrates with positioning technology – Rail Loc – from partner Machines with Vision, which provides precision positioning accurate to 30mm. This enables virtual track inspections from any location, transforming traditional site visits into efficient desktop reviews.

Switch detected on the AIVR Platform, with MVW’s logo confirming the position of the switch.

Key Platform Capabilities Include:

- Interactive digital patrolling diagrams: Schematic representations of track layouts with clickable navigation for rapid inspection of specific S&C sets.

- Automated asset detection: Machine learning algorithms automatically identify and geographically map track components, defects, and points of interest.

- Multi-stream synchronisation: View thermal, visible, line-scanning, geometry data and more for comprehensive assessment.

- Historical tracking: Compare conditions across multiple inspection runs to identify developing issues and trends.

- Data export and sharing : Export inspection data, reports, and imagery for maintenance planning and cross-team collaboration.

Implementation

The Class 153 VIU programme represents a comprehensive transformation of railway inspection methodology. The implementation included:

Fleet Conversion

Beginning in 2023, with expanding works up until 2025, a series of Class 153’s were transformed into Visual Inspection Units and Track Condition Monitoring Units, and were equipped with AIVR technology, creating an autonomous fleet capable of operating data or night on lines open to traffic at speeds from 0 to 70mph.

Collaborative Approach

The project demanded rapid execution and innovative collaboration. A core project team brought together engaged members from all stakeholder groups, with route colleagues positioned front and centre throughout the development process.

Technical Innovation

The team created unmanned autonomous vehicles with all data collection integrated in the cloud through the AIVR Platform. A web-based interface was developed for data access, enabling engineers to conduct virtual inspections without specialised software.

Progressive Capability Expansion

The programme adopted an iterative approach, with initial systems proving value before additional capabilities were systematically deployed across the fleet, for example STREX structural examination cameras.

Results

The Class 153 VIU programme has delivered transformational improvements in railway inspection and efficiency:

- 50% reducing in on–foot inspections, significantly enhancing worker safety by reducing trackside exposure.

- Recognition with Safety Achievement of the Year at the National Rail Awards 2023, acknowledging the programmes safety impact.

- Rapid data access, with inspection footage and geometry data available online surely for review.

- Anonymous operation, with trains operating at line speeds up to 70mph, capturing comprehensive data without track possessions.

- Comprehensive coverage of S&C inspections, rail inspection, structures inspection, lineside assets inspection and more, capturing necessary angles and conditions.

Key Benefits

Enhanced Safety

The most significant achievement of the Class 153 programme is the dramatic reduction in workers exposed to trackside hazards. By enabling remote inspections, the system eliminates the need for personnel to conduct routine on-foot patrols during the night-time hours or daytime possessions. This fundamental shift in working practice directly addresses the safety concerns that catalysed the project following serious incidents, including the approaching ban on red zone working.

Operational Efficiency

Virtual inspections transform resource deployment across the network. Engineers can review multiple locations from a single desk, eliminating travel time and enabling faster response to emerging issues. The ability to operate on lines open to traffic removes the need for service-disrupting possessions for routine inspections, improving both passenger and freight operations whilst maintaining rigorous safety standards.

Data-Driven Maintenance

The integration of multiple data streams enables sophisticated analysis previously impossible with manual inspections. Engineers can correlate thermal data with geometry measurements, track visual degradation over time, and identify patterns that indicate developing problems. This predictive capability supports the transition to Risk-Based Maintenance strategies, optimising intervention timing and resource allocation. Automated asset detection and defect detection streamline the inspection process, allowing engineers to focus on assessment and decision-making rather than manual review.

Comprehensive Documentation

Every inspection creates a permanent, time-stamped record accessible to authorised personnel. This comprehensive documentation supports compliance reporting, provides evidence for maintenance decisions, enables historical trend analysis, and creates a valuable knowledge base for training and continuous improvement initiatives.