18/06/2025

Rail Safety Week Day 3: Detecting Hotspots Before They Become Incidents

The Safety Challenge of Overheating Infrastructure

Railway infrastructure relies on a vast network of electrical and mechanical components, all of which must operate reliably in demanding conditions. Over time, faults can develop that cause these components-such as conductor rails, connectors, and cables to overheat. These thermal hotspots are often invisible to the naked eye and can remain undetected until a failure occurs, which can lead to equipment failure, fires, or costly service disruptions, putting both staff and passengers at risk.

Traditional visual inspections can often miss early thermal signs of potential future equipment failure because until there is a visible sign of component degradation – these signs are invisible to the naked human eye. As a result, these undetected thermal hotspots can get worse over time, potentially leading to equipment failure which can severely impact rail services and delay passengers. And further costs can be incurred due to the emergency repair work which is suddenly required and is often more expensive than planned maintenance work. Manual inspections also expose staff to hazardous environments, often in poor weather or at night.

How AIVR Improves Safety via Thermal Hotspot Detection

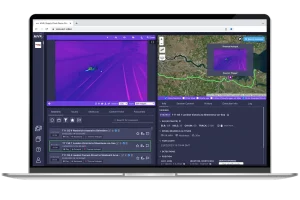

By integrating high-resolution thermal cameras onto in-service trains, AIVR Thermal captures thermographic imagery along the conductor and running rails during normal operations.This data is automatically uploaded to the AIVR Platform for online review, where advanced machine learning models analyse the footage to detect abnormal heat signatures and evolving hotspot conditions. AIVR Thermal is widely used in the rail industry, by Network Rail, as it enables continuous, remote surveillance of critical assets, ensuring early detection and intervention before issues escalate.

With AIVR, Teams can:

- Detect Hotspots Automatically: Machine learning analyses thermal video to identify abnormal heat signatures and developing hotspots along rails and cables.

- Receive Instant Alerts: Automated notifications pinpoint the exact location and severity of hotspots, enabling rapid, targeted responses.

- Track Hotspot Progression: Monitor how hotspots change over time, supporting predictive maintenance and timely interventions.

- Switch Between Thermal & Visible Views: Engineers can compare thermal and standard video footage for detailed analysis and safer planning of repairs.

- Share Precise Reports: Export annotated videos, images, and data for efficient repairs, safety briefings, and maintenance planning.

Safety Benefits of Remote Thermal Inspection

- Reduce the need for routine manual inspections in hazardous areas – instead engineers can remotely inspect the rail environment, keeping them safer and reducing exposure to live tracks and electrical hazards.

- Enables early intervention, preventing fires, equipment failures, and service disruptions that could endanger staff and passengers.

- Supports a proactive, predictive maintenance approach, reducing emergency call outs and unplanned trackside work.

- Keeps both staff and passengers safe by ensuring critical national infrastructure is monitored more frequently and comprehensively, with issues addressed before they escalate.

- Improves efficiency and coverage, allowing more of the network to be monitored in less time and with fewer resources.

“It’s a fantastic project and the outputs greatly improve Network Rail’s ability to predict and prevent failures, improving the service we provide to our customers.” Principal Engineer, Network Rail.

This proactive approach improves safety for staff and passengers, supports predictive maintenance, and increases efficiency by allowing more of the network to be monitored quickly and thoroughly.

Want to learn more or see AIVR in action? Get in touch!