13/05/2025

One Big Circle, KONUX, and Network Rail: Teaming Up for Smarter Rail Maintenance

One Big Circle and KONUX, in partnership with Network Rail, have deployed an integrated solution to support more effective maintenance of Switches and Crossings (S&C), critical yet complex components of the rail network.

Rail infrastructure in the UK is under increasing pressure to deliver enhanced performance and safety. With growing demands to improve passenger experience and ensure reliability, the industry must transform their maintenance approaches from reactive to predictive. This shift is particularly critical for Switches and Crossings (S&C) – high risk track assets that play a fundamental role in managing rail traffic flow and enabling route flexibility.

Due to significant dynamic forces and continuous use, S&C are prone to wear and deformation. Maintaining these assets requires frequent inspections, which have traditionally relied on on-site track workers operating within restrictive possession times – often during the night or in low-visibility conditions. This approach not only introduces inherent safety risks for workers but also contributes to service disruptions and presents challenges in detecting faults before they become safety-critical.

Given these challenges, the industry increasingly recognises the value of data-driven insights to enhance S&C maintenance, enabling more efficient, predictive strategies that improve rail reliability and safety.

To overcome these challenges, German-based technology company KONUX and UK-based tech company One Big Circle have teamed up to integrate their expertise and technologies in partnership with Network Rail’s Research and Development Team. Their collaboration integrates One Big Circle’s high-definition line-scanning visual data on the AIVR Platform with the KONUX Switch solution, delivering a comprehensive, data-driven approach to S&C predictive maintenance for engineers.

About One Big Circle’s Rail Inspection Technology

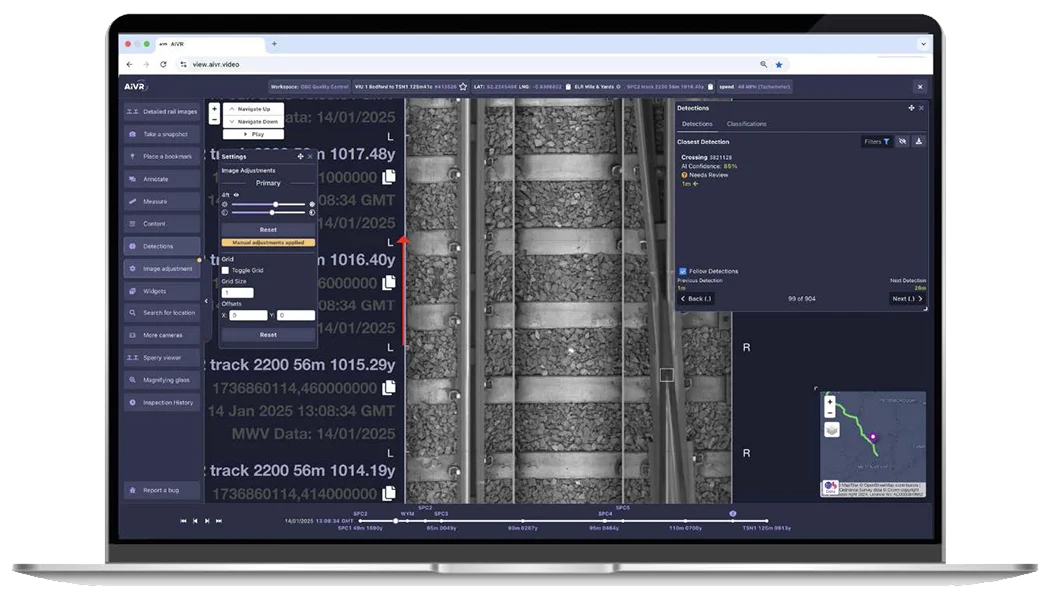

One Big Circle’s rail inspection technology – AIVR Focus – is a fully integrated, end-to-end system that utilises line-scanning cameras deployed on maintenance vehicles, such as the VIU Class 153’s, as well as in-service passenger fleets across the UK. These cameras capture high-resolution imagery alongside additional video data, including forward facing and thermal, as well as locational and track geometry data, providing a comprehensive visual record of the rail network.

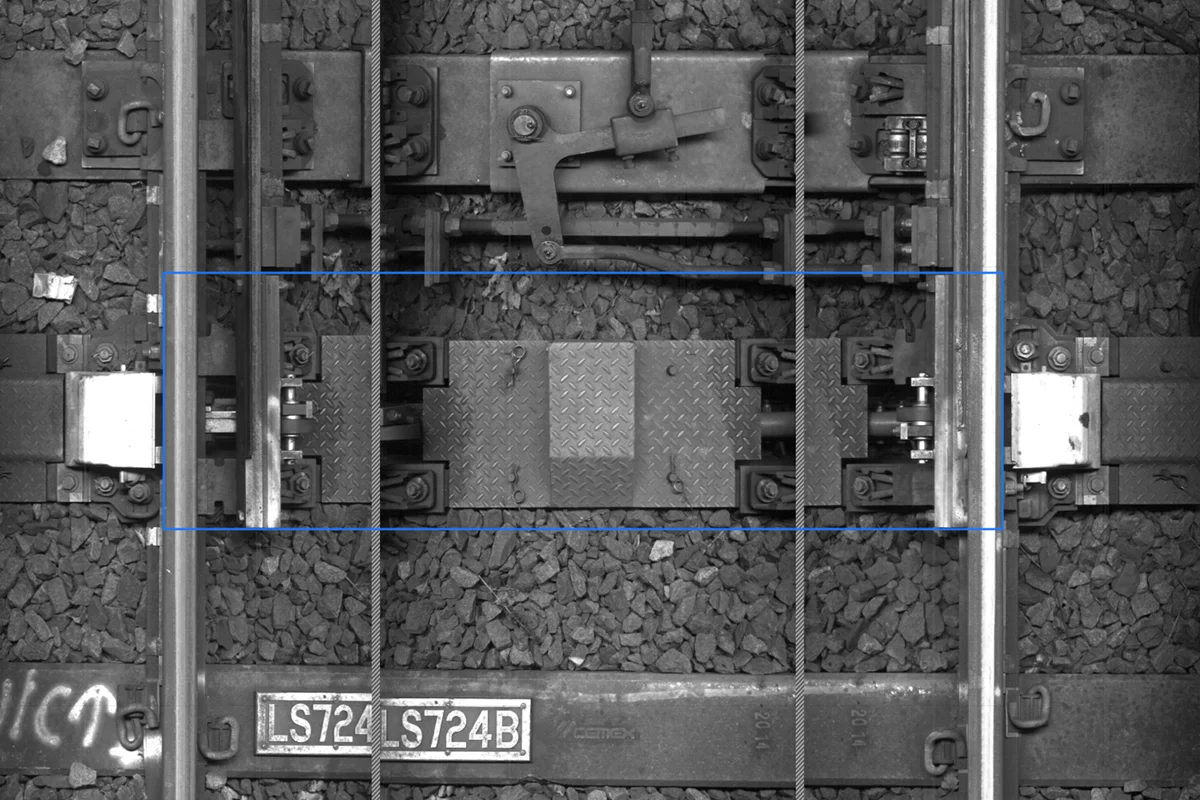

Switch detected by Machine Learning on the AIVR Platform.

Crossing detected by Machine Learning on the AIVR Platform.

The data is automatically uploaded to the cloud-based AIVR Platform in near-real time, enabling industry professionals to access and review inspection data, significantly reducing the need for trackside surveys and enhancing both safety and efficiency.

Online Rail Inspection interface on the AIVR Platform.

Machine learning (ML) and artificial intelligence (AI) are applied to the data to automatically detect key track components such as joints, switches, and crossings, directing engineers straight to the relevant areas for a faster and more efficient review. ML and AI models also proactively identify track defects, alerting users to areas of concern enabling quick, informed maintenance decisions. The AIVR Platform also provides powerful analysis tools, allowing users to annotate the line-scanning imagery to highlight points of interest, e.g. a crossing nose, measure track components, zoom in for detailed inspections, review historical data to identify changes over time, and export key data for reporting and decision-making. All insights are centralised, enabling collaboration and more effective maintenance across planning teams.

About the Konux Switch

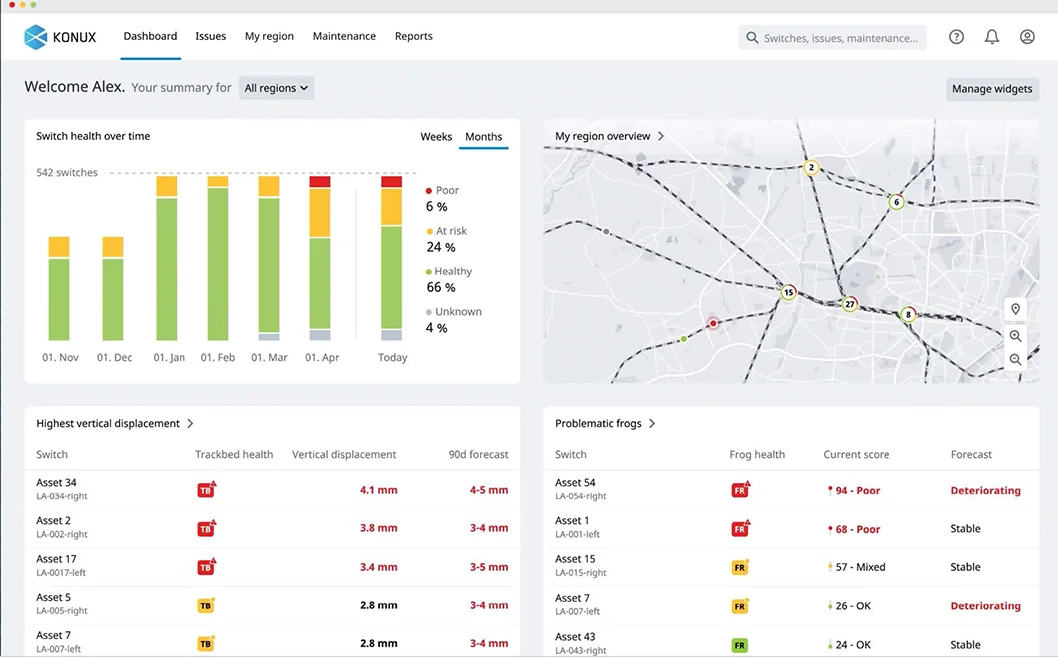

A major challenge in managing S&C is that their condition cannot always be reliably determined by visual appearance alone but rather by their operational behaviour when trains pass over. The KONUX Switch solution, addresses this challenge with an end-to-end predictive maintenance system that continuously monitors and analyses the health of key switch components such as the trackbed, frog, and point machine.

KONUX Switch installed on the track.

This is achieved through AI-driven analytics and in-track IIoT devices that continuously capture data. AI models analyse patterns in asset conditions, providing actionable insights via the KONUX Switch UI. These insights ultimately allow for better maintenance planning by helping infrastructure managers anticipate failures, optimise maintenance timing, and improve overall network reliability.

The KONUX Switch’s data processing system includes:

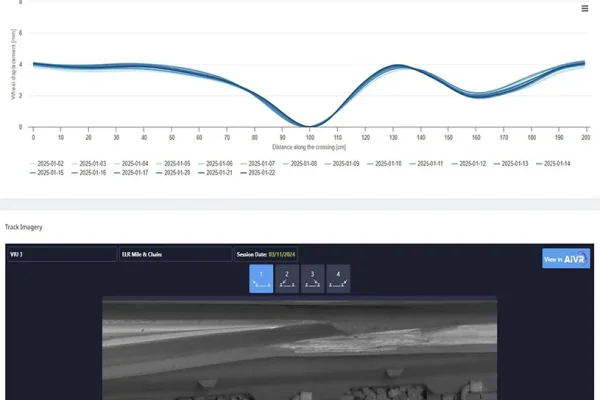

- A reconstruction of the vertical displacement of switches and crossings by leveraging advanced IoT devices, a Digital Twin model, and intelligent data processing.

- A displacement reconstruction algorithm used for trackbed condition assessment.

- Mathematical and physical models, including digital twin multibody simulation and finite element method models that recreate the vertical movement of the wheels as they travel through the crossings.

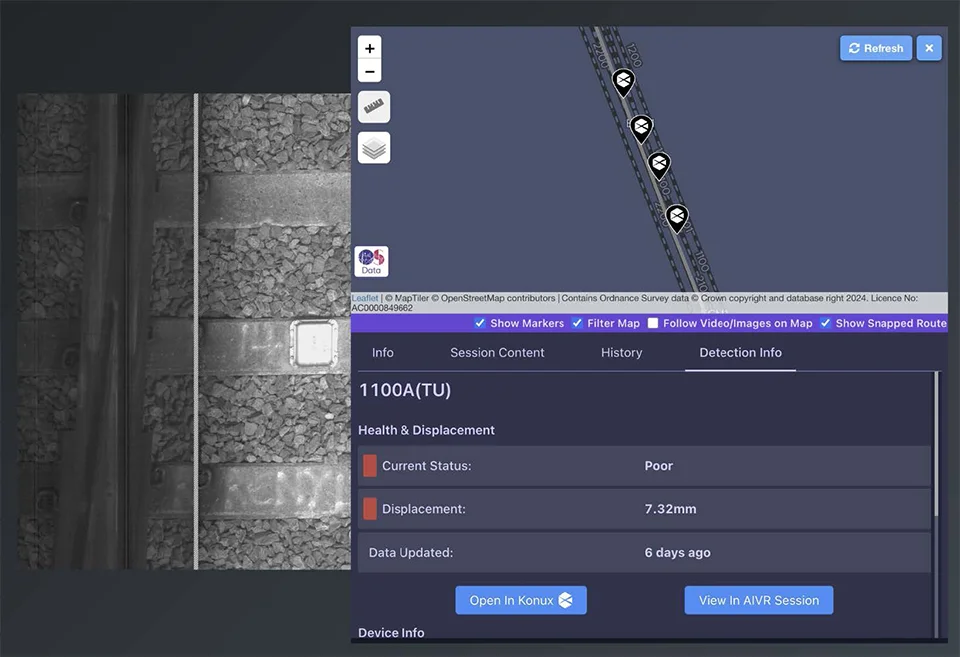

Health metrics of switches displayed on KONUX Dashboard.

These advanced models help determine S&C wheel-rail forces, wheel-rail dynamics and the results are analysed holistically to address S&C health, maintenance and management.

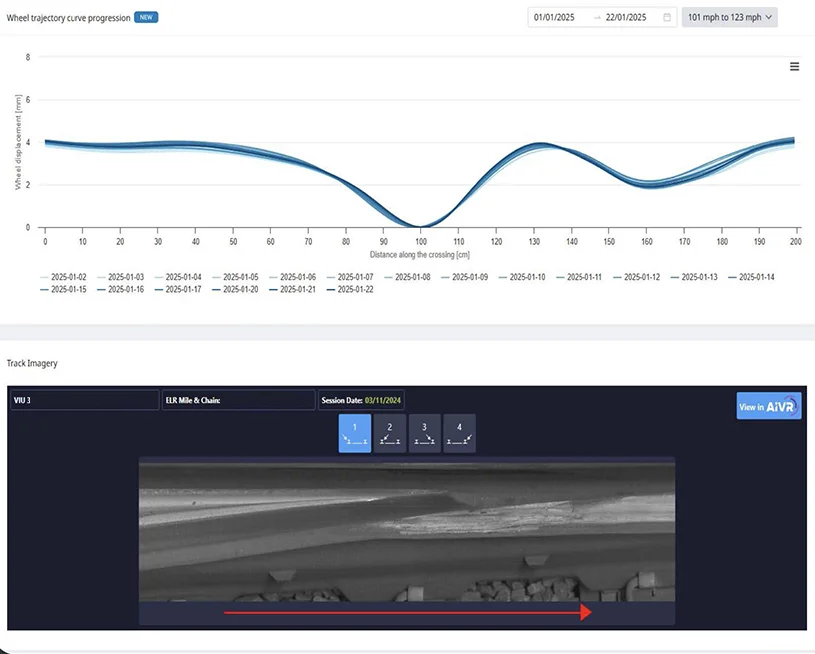

S&C track structure deformation and deterioration are driven by the contact force between the wheel and rail. The size and pattern of this force is determined by wheel-rail dynamic interaction, which in turn depends on how the wheel moves along the rail. KONUX Switch continuously monitors this relationship, providing valuable insights into switch health. Their Wheel Trajectory Reconstruction (WTR) feature reconstructs the real movement of wheels over crossings, providing a direct view of their interaction with the track. This enables the precise identification of key impact forces and degradation trends, helping to predict wear and detect issues before they lead to failures.

KONUX Switch and AIVR Integration

In September 2024 KONUX and AIVR began working together with Network Rail’s Sussex route and the central R&D team to develop, test and assess an integrated solution. The ambition was to deliver a holistic picture to the engineers where they were provided detailed AIVR imagery of the S&C that were being remotely monitored by KONUX Switch IoT devices.

Key Features of the integration

- Embedded AIVR line-scanning data with KONUX Switch UI, allowing users to review visual inspections alongside health metrics.

- Locational data precision, enabling precise asset identification.

- Integration of KONUX asset health data on AIVR, offering a holistic view of S&C conditions.

- Seamless navigation between the two platforms, ensuring maintenance engineers can contextualise issues effectively.

KONUX Switch health metrics displayed on the AIVR Platform.

A key feature of this integration is the ability to overlay KONUX Switch’s WTR with recent AIVR imagery of railhead conditions. The KONUX Switch UI presents progression curves based on statistically processed daily data from all passing trains. By integrating AIVR’s latest track images, engineers gain deeper insights into potential wear patterns and wheel unloading issues.

Wheel trajectory progression curve with visual AIVR imagery.

This powerful combination of tools enables engineers to contextualise data from remote condition monitoring systems, improving the planning and execution of maintenance activities.

The collaboration between One Big Circle, KONUX and Network Rail represents a major step forward in predictive maintenance for the rail industry. By combining visual inspection technology with advanced analytics, this partnership delivers a smarter, more proactive approach to railway infrastructure management, ensuring enhanced safety, efficiency, and reliability.

“Integrating the images from AIVR with the insights from KONUX is invaluable, as it gives us vital contextual information to help us understand root cause enabling us to scope work remotely, reducing boots on ballast and helping us to deliver a right first time intervention“. Engineer, Network Rail.

“This project with KONUX and Network Rail has been a fantastic example of the strength of collaboration in improving rail infrastructure management. By combining AIVR’s visual inspection technology with KONUX’s advanced analytics, we’ve created a powerful predictive maintenance solution that enhances safety and efficiency. It’s exciting to see what else our collaboration can bring“. Emily Kent, Co-founder, One Big Circle.

“The inventiveness and ingenuity demonstrated by our product and Engineering team continually amaze me. Being able to derive the wheel trajectory from a simple accelerometer is incredible – linking the outputs from this with the images from One Big Circle provide genuinely world class capability that surpass anything I have seen in my 25 year career“. Tim Flower, KONUX Account Director North Europe.

We are proud to share that this partnership between One Big Circle, KONUX, and Network Rail has won the Partnership category at the 2025 Railway Industry Association (RIA) RISE Awards, which recognises excellence and achievement within the UK rail supply community.

Winners of the Partnership Award – RIA RISE Awards 2025.