16/06/2025

AIVR STREX: Enhanced Remote Structural and Lineside Inspection Now Available on the AIVR Platform

We are excited to announce that AIVR STREX, the innovative remote structural and lineside inspection video technology developed by One Big Circle, is now widely available for all AIVR license holders to access directly on the AIVR platform.

Introduction to AIVR STREX

AIVR STREX (Structural Examination) represents a major leap forward in railway infrastructure inspection, building on the proven success of our award-winning AIVR FFV (Forward-Facing Video) technology. Where FFV systems focus on the track ahead, STREX adds outward-facing cameras to deliver a far broader view. Positioned on Class 153 Visual Inspection Units, these cameras capture both sides of the track, working alongside the forward-facing cameras to provide a comprehensive perspective of the entire track environment. This combined approach empowers engineers to remotely inspect critical external structures, such as bridges, tunnels, signals, and more, and the lineside environment.

All video captured by STREX is automatically uploaded to the cloud, making it instantly available for review and analysis through the AIVR Platform. This technology is now widely available for all AIVR license holders, enabling teams across the rail industry to benefit from enhanced inspection capabilities.

Why We Built AIVR STREX

Much of the UK’s railway infrastructure is decades old. Bridges, tunnels, signals, and track components require regular inspection and maintenance to prevent failures and keep the network safe and reliable. As these assets age, the need for efficient, accurate, regular, and safe inspection methods becomes ever more critical.

Traditional manual inspections present significant challenges: they expose teams to safety risks when working trackside, are often inefficient, and can delay the identification and response to critical issues. Recognising these challenges, One Big Circle developed AIVR STREX to transform how structural inspections are conducted – delivering a safer, more efficient, and highly effective solution.

But STREX isn’t just for structural inspection. Its high-quality, wide-angle imagery offers invaluable insight for any application where a clear and comprehensive view of the lineside environment is needed. Whether you’re monitoring trackside assets, vegetation, access points, or other features, STREX ensures you have the visual information required for informed decision making, delivering flexibility and value across a range of operational disciplines.

AIVR STREX is already in use by Network Rail engineers, empowering them to monitor external structural environments remotely and continuously, without the need to go trackside.

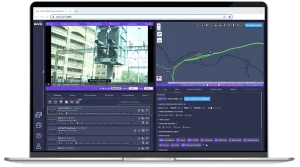

AIVR STREX data available on the AIVR Platform.

Transforming Structural Inspections

AIVR STREX, installed on Class 153 Visual Inspection Units, is transforming the way structural and lineside inspections are performed. By addressing the safety risks and inefficiencies associated with manual inspections, STREX delivers a safer, more efficient, and secure solution for infrastructure management.

Key Features of AIVR STREX

- Remote Inspection: Users can now inspect external structural environments remotely, reducing the need for site visits and minimising safety risks.

- Continuous Monitoring: The STEX system is permanently installed on several Class 153 trains, enabling ongoing monitoring of infrastructure.

- High-Quality Imagery: STREX delivers exceptional video quality of lineside vegetation, access points, Overhead Line Equipment (OLE) and other trackside assets, supporting a wide range of operational disciplines.

- Online Review with Digital Tools: Access and analyse video recorded by the STREX TLC cameras directly on the AIVR Platform. Switch seamlessly between left and right camera views for full visibility of both sides of the track. Use digital tools to annotate footage, locate video and assets, review route history, and export images or video for reporting and analysis.

- AI and Machine Learning: Automated detection and identification can be applied to trackside assets such as stanchions, signals, and speed boards, streamlining the inspection process.

AIVR STREX TLC Box installed on Class 153.

Innovative System Design

The STREX system consists of:

- STREX TLC (Tail Lamp Camera) Box: Equipped with two outward-facing cameras in a Network Rail-approved housing unit.

- Wide Field of View: Cameras positioned in opposite directions capture video from both sides of the track, providing a broader perspective than standard forward-facing cameras.

- Excellent Image Quality: Large, highly specialised image sensors ensure excellent video clarity, even at high speeds and with cameras angled towards the lineside.

- Reliable Power Supply: Built-in power supplies in each TLC box guarantee reliable data capture whenever the train is powered and in motion.

- Flexible Installation: STREX TLC units can be mounted on the front and/or rear of trains for comprehensive coverage.

- Optimised Performance: The system operates effectively at high speeds and in low-light conditions, with exposure time controls to eliminate motion blur.

- Low-Latency Exposure Adjustment: Quick adaptation to changing light conditions ensures consistent video quality.

- Global Shutter Technology: Prevents visual distortions such as warping or skewing, common issues with rolling stock shutters.

- Near-Real-Time Data Transmission: Video data is automatically transmitted via 4G/5G, making it securely accessible within minutes on the AIVR Platform for immediate review and analysis.

Images from left and right STREX cameras stitched to create panorama for illustrative purposes.

Images from left and right STREX cameras stitched to create panorama for illustrative purposes.

With AIVR STREX now widely available on the AIVR platform, users can access, review, and analyse structural and lineside inspection data with unprecedented ease and efficiency.

Don’t have an AIVR License?

You’re missing out! Get in touch to learn how you can benefit from AIVR STREX and the wider AIVR platform.