22/11/2024

What is Rail Infrastructure Monitoring?

Rail infrastructure monitoring is a critical service that supports many of the engineering decisions involved in maintaining the rail network. It involves utilising a variety of technologies to revolutionise the inspection and assessment of rail infrastructure, enabling safer monitoring of assets including track, signals, and structures.

The ability to remotely review rail infrastructure using digital platforms reduces the necessity to conduct manual inspections, helping keep boots off ballast and enhancing the safety of track workers. As the volume of trains running on the rail network constantly increases, and access to the track reduces, the implementation of intelligent monitoring systems is crucial.

The Role of Infrastructure Monitoring in Rail Safety and Efficiency

Effective infrastructure monitoring is essential for preventative maintenance that addresses potential faults before critical failure. A proactive approach improves the safety and efficiency of rail operations, providing benefits to both workers and passengers by helping prevent accidents and minimise network downtime. The complexity of modern rail networks drives the demand for sophisticated monitoring technologies that are capable of providing engineers with up-to-date, accurate data.

Infrastructure Monitoring and Track Condition Monitoring Techniques

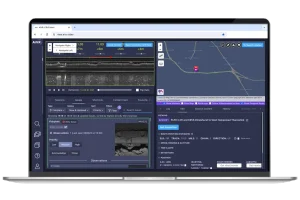

Infrastructure Monitoring utilises a range of technologies, including high-resolution cameras and sensors, to provide detailed insights into the condition of track componentry on the railway. This data is available for review remotely, significantly reducing the need for engineers to conduct on-site inspections. One Big Circle’s AIVR Focus system enables remote monitoring in rapid time, enhanced by AI to detect and conditions assess track components including joints, S&C, electrical cables, and defects on the rail head. Track inspection data, in addition to the multiple streams of data available online as part of the wider AIVR (Automated Intelligent Video Review) product suite, supports railway engineers in making informed, timely decisions that ensure track safety and reliability.

Remote track inspection on the AIVR Platform.

Case Study: How Network Rail Used AIVR to Enhance Remote Monitoring During Covid-19

The Covid-19 pandemic accelerated the need for effective remote monitoring solutions in the rail industry. The implementation of lockdown measures in early 2020 resulted in an unprecedented demand for engineers to be able to remotely view data from home. Imagery captured from trainborne cameras had many barriers to access, typically stored in hard drives on trains and requiring couriers to take the data to offices for review. Network Rail’s implementation of AIVR showcased a swift and effective transition to advanced cloud-based video analytics.

Following successful trials, AIVR was increasingly adopted across Transport for Wales, Network Rail and the wider rail industry, using a range of portable devices and integrations with permanent cameras to capture forward facing video and thermal imagery of the rail network. The ability for engineers to utilise this data to monitor railway conditions remotely was crucial to ensure the safety of both track workers and passengers who relied on trains during the pandemic. For more detailed insights into this transformation and following developments, a case study is available here.

How Can AIVR Help with Railway Infrastructure Monitoring?

AIVR offers a comprehensive solution for effective rail infrastructure monitoring, which is a critical element of maintaining a safe and reliable railway. By providing remote access to various streams of data in rapid-time, AIVR empowers engineers with insights into critical national infrastructure, which are made more accessible to a wider base of end-users through integrations with other platforms. For example, AIVR data is viewable through a widget embedded in a Network Rail platform to enable seamless work between sources for staff and avoid unnecessary siloing of data. It is key to have an open approach to sharing data to maximise information available for end-users and enable informed decision making.

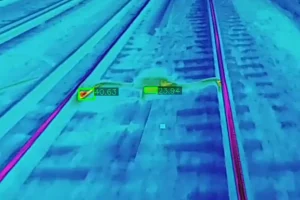

Planning of proactive maintenance activities is further enhanced by additional intelligence from Machine Learning and Artificial Intelligence, optimising asset management through the automated detection of faults such as thermal hotspots or wet beds before critical failure. With advanced capabilities including overhead line monitoring, detailed line-scanning track imagery, and track geometry data, the innovative AIVR product suite supports remote condition monitoring across a wide range of rail disciplines.

Thermal hotspot detection.

One Big Circle look forward to our team and AIVR to playing a key role in the rapidly evolving field of Infrastructure Monitoring. As advancements in technology and AI drive the collection and analysis of increasing data, this area is set to grow significantly. Our approach centres on collaboration—working closely with customers and other suppliers to deliver insights from infrastructure monitoring that are greater than the sum of their parts.

Contact our team today to discover how AIVR can support your digital journey in rail and drive operational excellence.