Fast & focused: how to get sharp shots of rail tracks from moving trains

Written by Joe Pontin.

Introduction

Here at One Big Circle, we’re proud of the complex engineering behind our track-monitoring video-systems. We’d like the world to know more about our innovative solutions – so we asked an experienced journalist to take a fresh approach to our story, and help folks in the rail industry and beyond get a deeper understanding of what we do.

In the first of a series of articles about the work of One Big Circle’s engineers, Joe Pontin explains how the engineers at OBC are completely rethinking the approach to gathering video images of tracks, to help keep passengers and workers safe.

Setting the scene

The lab

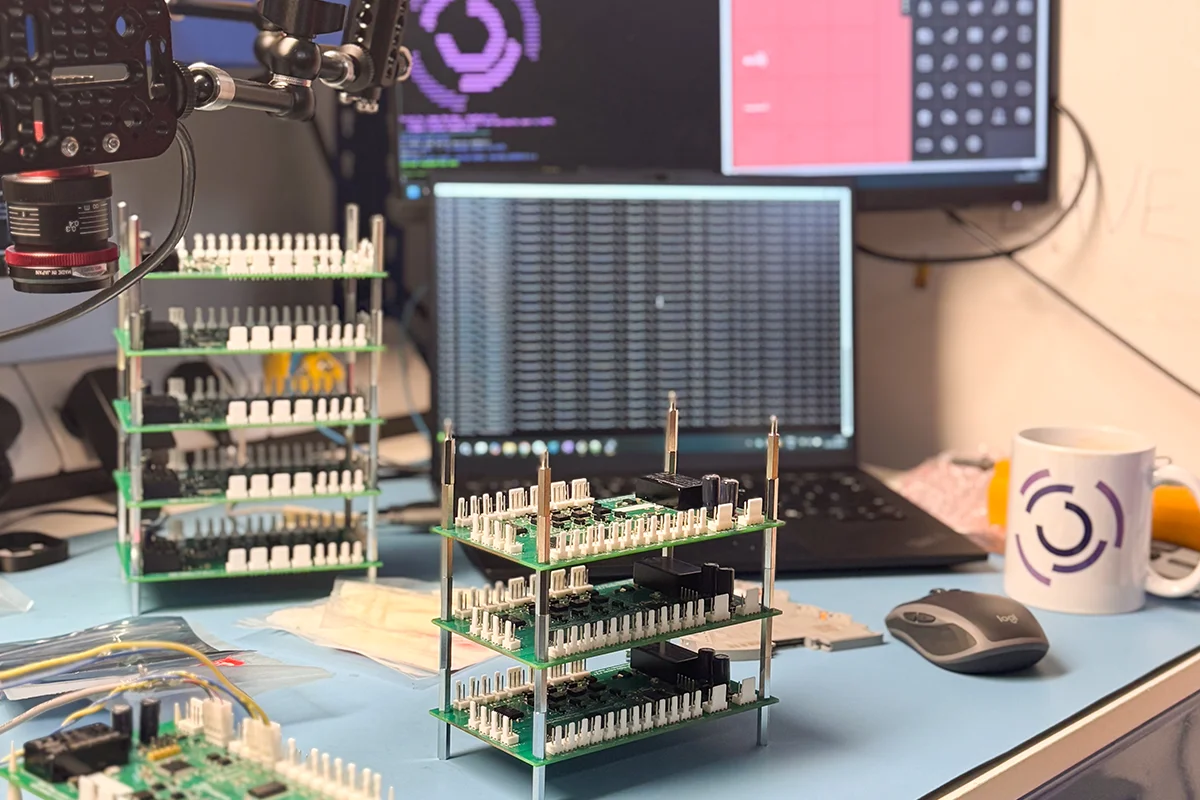

It’s a quiet moment in the lab at One Big Circle. Above the whir of the server fans, you might even hear the faint rumble of trains rolling out of Bristol’s Temple Meads Station, less than 30 metres away.

On this chilly winter mid-morning, my first visit to One Big Circle, the disc sander and the pillar drill are still and silent. The other power tools congregate mutely beneath the bench, their gleaming steel teeth frozen. The lathe lies idle, and the shake table slumbers peacefully. Most of OBC’s test engineers are in a meeting, and disassembled cameras and other components lie across the benches. Only systems engineer George Handford is around, tinkering quietly at the Clean Electronics bench. “It’s not always like this,” he says. It can get noisy, he explains; and hot; and smelly. When the lathe is spinning, or the shake table is vibrating, the sound is “intense”.

So usually this is a hive of activity, and one fundamental to the success of this growing tech firm. “The lab is where everything starts,” according to One Big Circle (OBC) co-founder Emily Kent. “When we describe how OBC works as an entity, we begin with data capture – effectively a series of images. We need the lab to ensure we capture that data in the right way in really difficult conditions, and the lab is the bedrock of that.”

“Data is the new oil,” British mathematician Clive Humby famously said back in 2006; and in this case, the data OBC gathers on Britain’s trail network fuel an operation with vital real-world consequences.

This data will help keep trains and rail workers safe.

Meet the writer

Joe Pontin is a writer and editor with 25 years’ experience as a journalist on local newspapers and BBC magazines. He is a former managing editor of BBC Countryfile magazine.

We asked Joe to bring his knack for clarity and storytelling to the world of railway technology. He said: “Like most passengers on the 8.15 to Bristol Temple Meads, I had no idea of the complex engineering that goes into running our railways safely. What I’ve learned so far had been fascinating, and far more elaborate than I expected. I hope to tell the story of this changing technology in an engaging and comprehensible way.”

The leap

In some ways the OBC offices are like many others, with neat rows of desks and monitors. But glance up to the walls and things are different. Live screens display video shot from trains travelling all over the UK; and one monitor displays a live destination board, featuring trains fitted with Automated Intelligent Video Review (AIVR) devices.

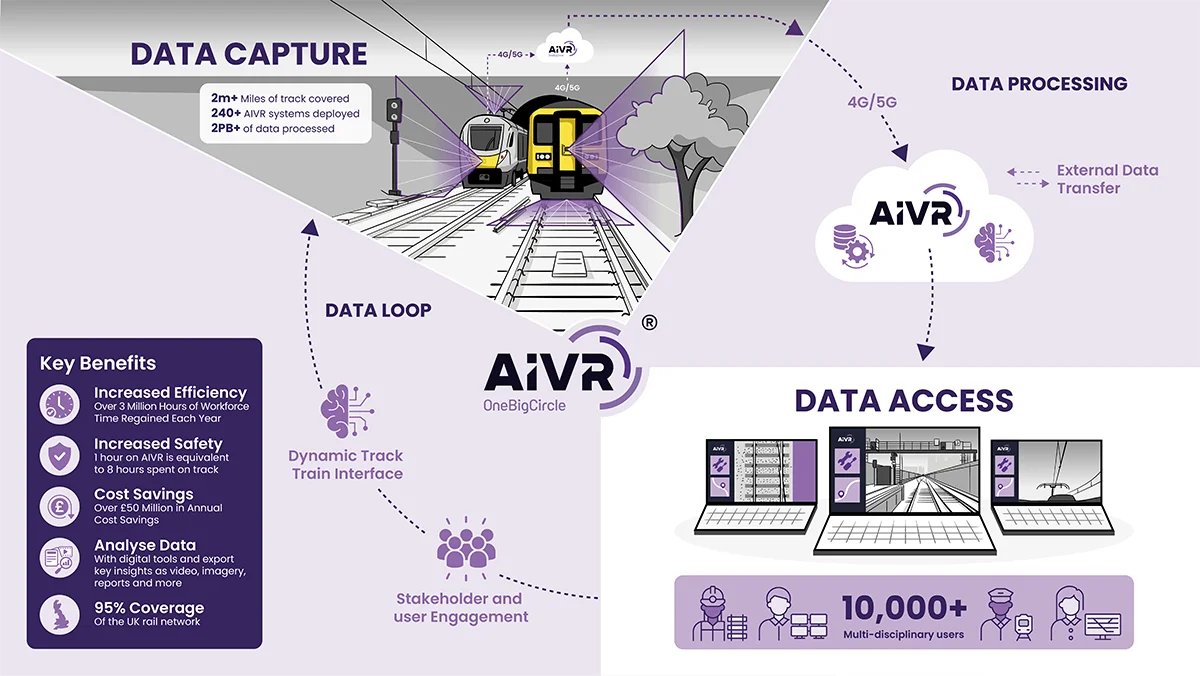

AIVR cameras constantly gather images from trains moving all around the network, uploading to the cloud via 4G/5G, explains Emily. Rapidly sharing images, she points out, is an important benefit of AIVR – allowing people from all relevant engineering disciplines to monitor the state of the network and identify problems in close to real time.

Diagram of how AIVR’s technology captures, processes, and provides access to vast amounts of rail network data

The ready accessibility of these images from the rail network was a huge leap forward for the industry. Where previously data had been stored on hard drives, now most freshly captured footage is almost instantly available.

Why is this so important? Well, the state of tracks and the trackside environment is crucial for safety – and can change rapidly.

Trains are, obviously, big beasts. So the tracks they run on, and the sleepers and stones that support the tracks, take a lot of punishment. Even with tracks made of high-quality steel alloy, wear and tear is inevitable. Faults in the track have the potential to cause serious accidents if not quickly spotted and fixed.

So, to keep passengers and rail workers safe, rail engineers need to find those faults as soon as possible. But with more than 20,000 miles of track in the UK, that is a big task.

Alongside physical inspections, by 2019 the industry had deployed increasingly sophisticated devices to monitor UK railways, including the use of video. But in that year, One Big Circle set about adding their own video technology to the industry, with the aim of dramatically scaling up the quantity and quality of information about Britain’s rail tracks. As Emily puts it, “Engineers need to see what they need to see to respond to issues as quickly as possible. This aligns with both the drive for increased safety in the industry as well as the digitisation of railway monitoring.”

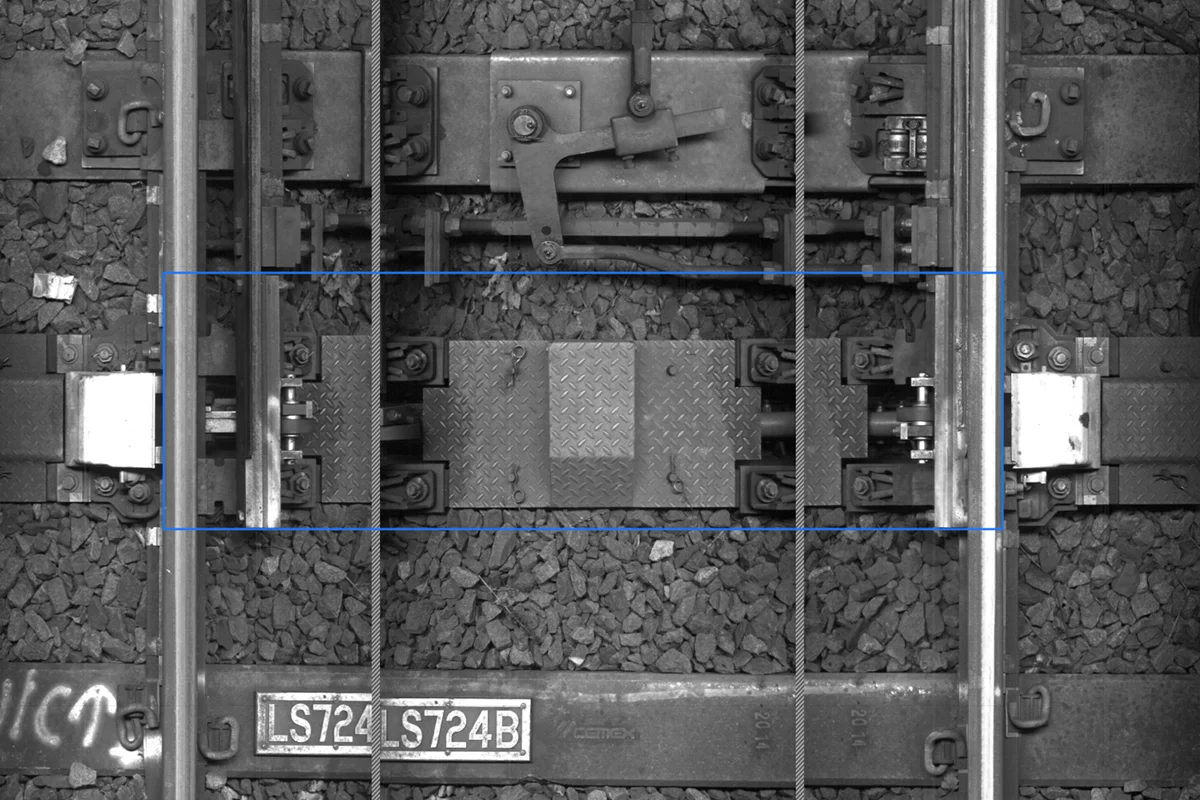

Rail inspection on the AIVR Platform

But as I learn in a series of conversations with the engineers here, the gains brought by AIVR have been hard won. The problem-solving behind the intelligent video now deployed daily across the network is more intricate than some might imagine.

Effective data capture

In computing terms, these problems are essentially issues of data capture – the gathering of raw facts from the physical world, in digital form. Once organised, or processed, data may yield information – in other words, something useful.

But the focus in this piece, and of the series to follow, is on that first essential phase of this process, data capture.

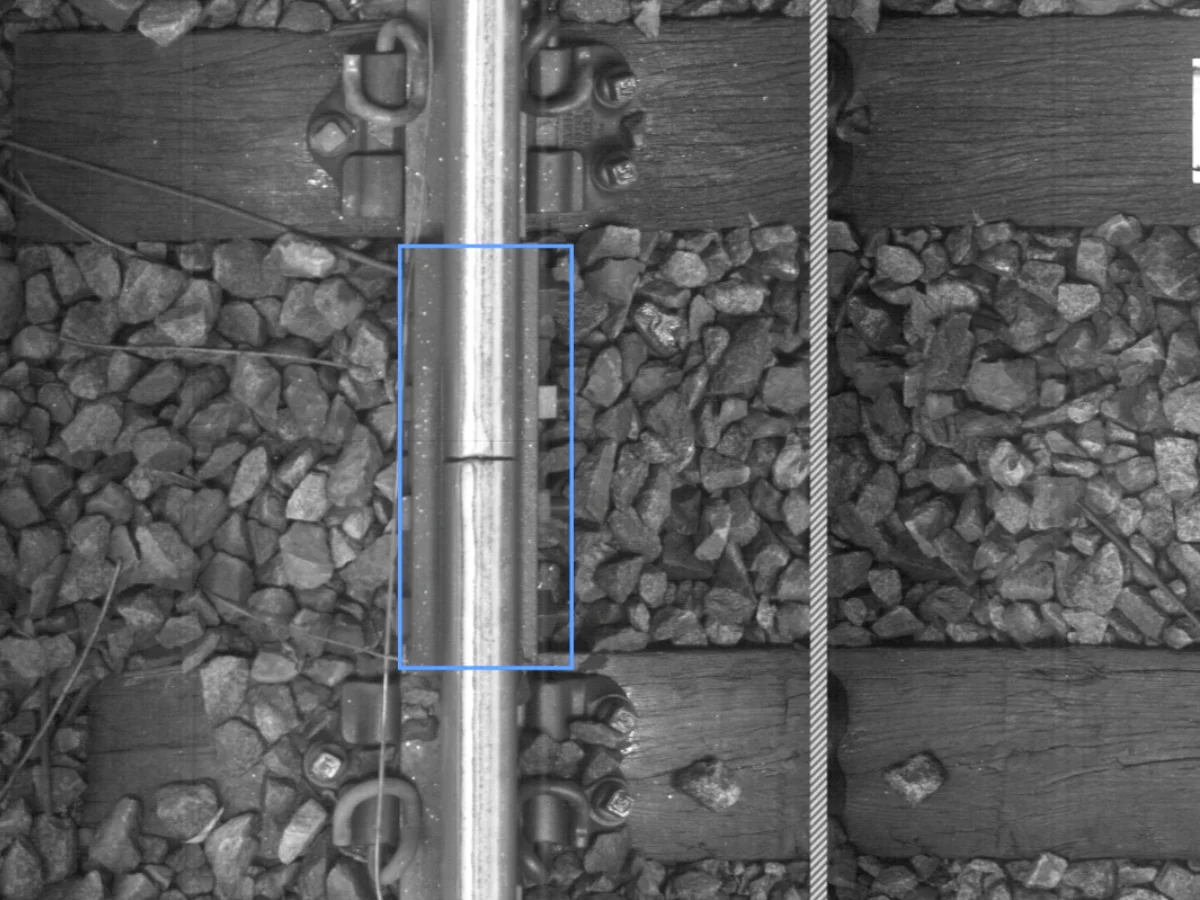

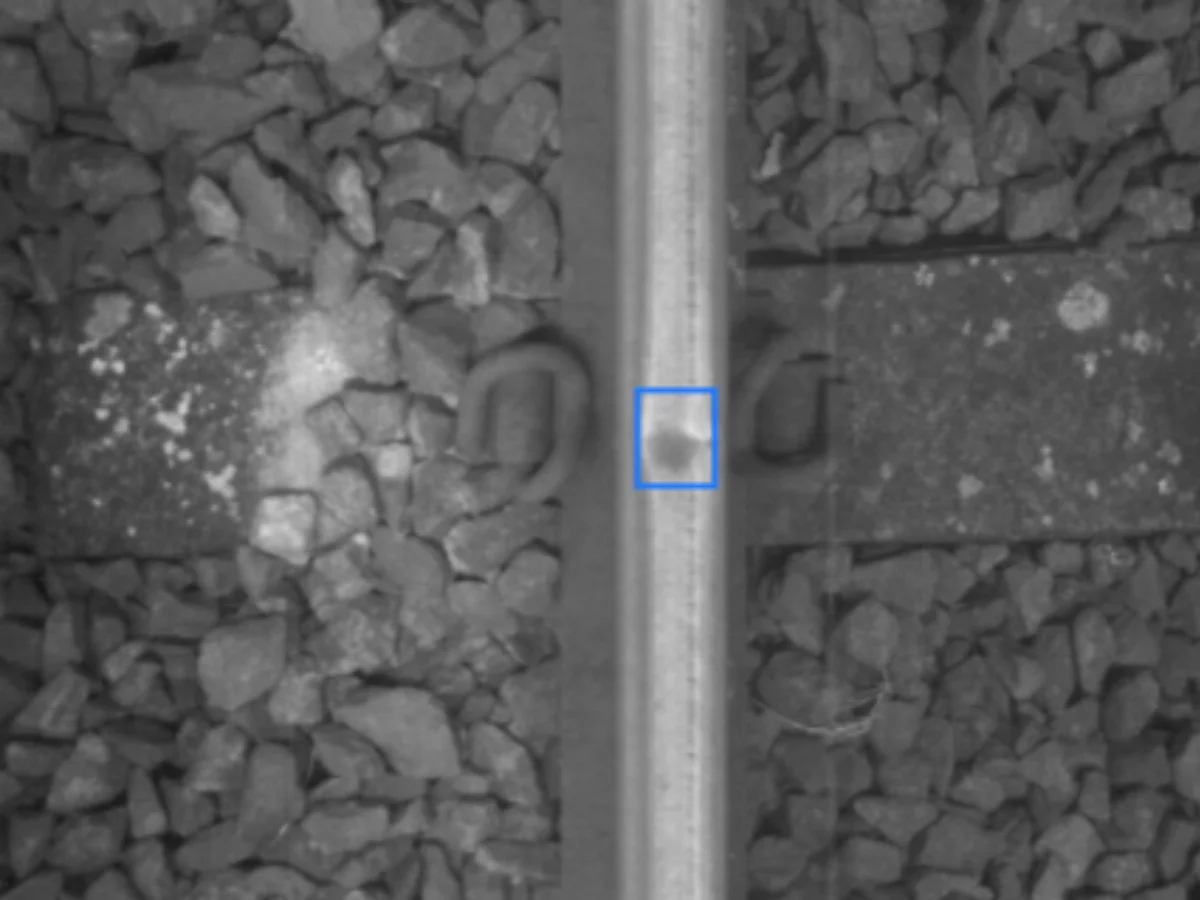

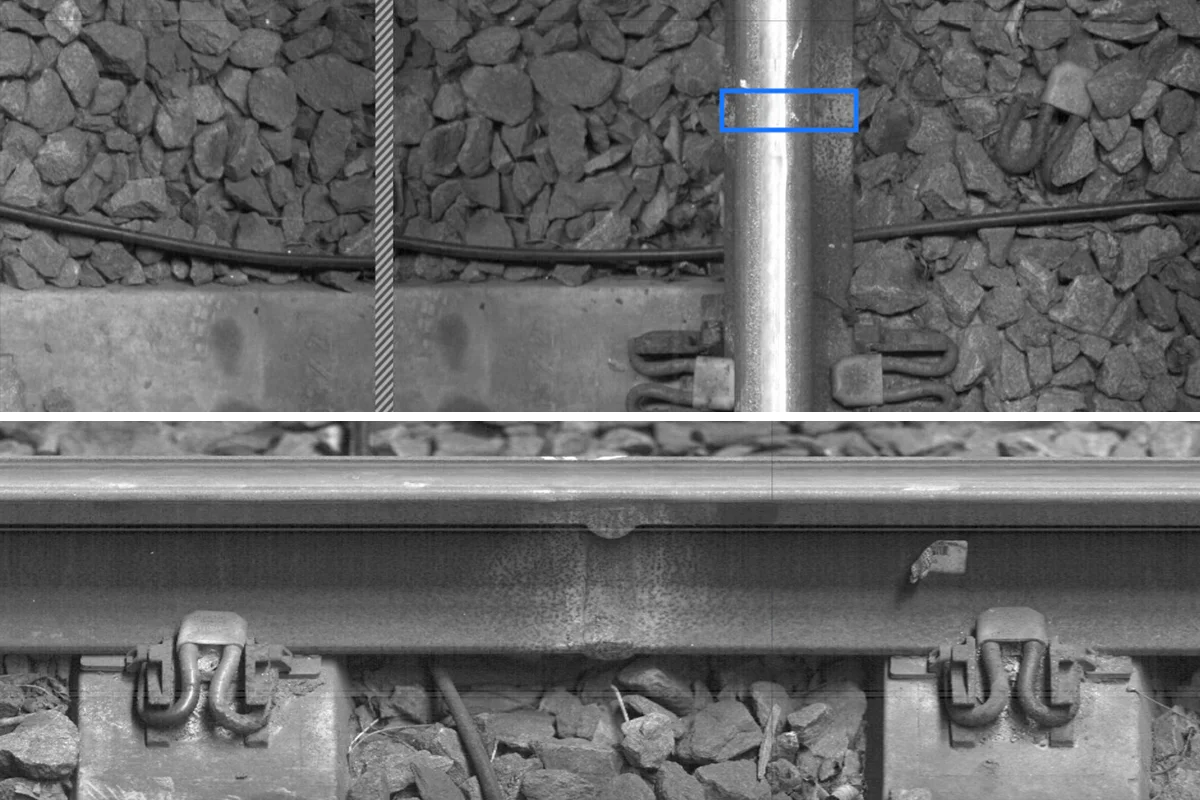

That may sound a little abstract, so let’s bring the real world in. If devices are to successfully identify problems with tracks, they have to gather good quality data in sufficient quantities. In the case of video, that means sharp images, and plenty of them. And to be any use to the engineers who will fix a faulty rail, these images need accurate positioning data, allowing the location of the problem to be pinpointed.

Sharp images and accurate positioning the just two challenges of OBC’s data capture mission. There are many more – from protecting devices in harsh conditions, to giving them the autonomy they need, and keeping their power supply on. We’ll deal with each of these in more detail as this series of articles unfolds.

A note on what to expect from this article

As a writer, I am new to the complexity of these challenges myself – but now it’s my job to explain them to you.

I hope that this pieces and those to follow will be helpful, whether you are an experienced rail industry pro, a software engineer, or even a curious lay person – a passenger on the Paddington train.

In writing for all three of these readers, my rule is always to strip things back to basics and build up again, so everyone can follow my thread as we venture into more complex territory. I hope that in doing so, more knowledgeable readers will forgive me for occasionally seeming to over-simplify.

Part 1: The quest to capture sharp images

The obvious place to begin is perhaps the most basic requirement of a video monitoring system: the quality of images captured by the cameras.

For the engineers behind AIVR, the challenge is to capture and share images of sufficient quality to diagnose a range of problems on the rail network, from broken or damaged rails to electrical faults on and around the trains.

OBC has worked hard, against the odds, to overcome the physical constraints (of which more below) – and has succeeded in capturing an abundance of really good imagery. But can they find ways to make all the images of equally high quality?

Technical challenges

One hundred percent perfect images – it seems a bold but not unreasonable aspiration. After all, many modern cameras seem smarter and more responsive than ever. We can all take great shots, even in poor light; even – or perhaps especially – with our mobile phones.

So why don’t modern cameras always deliver clear images? Well, it seems the demands on cameras located on trains are far more complex than you might imagine, and all these demands influence the images they shoot.

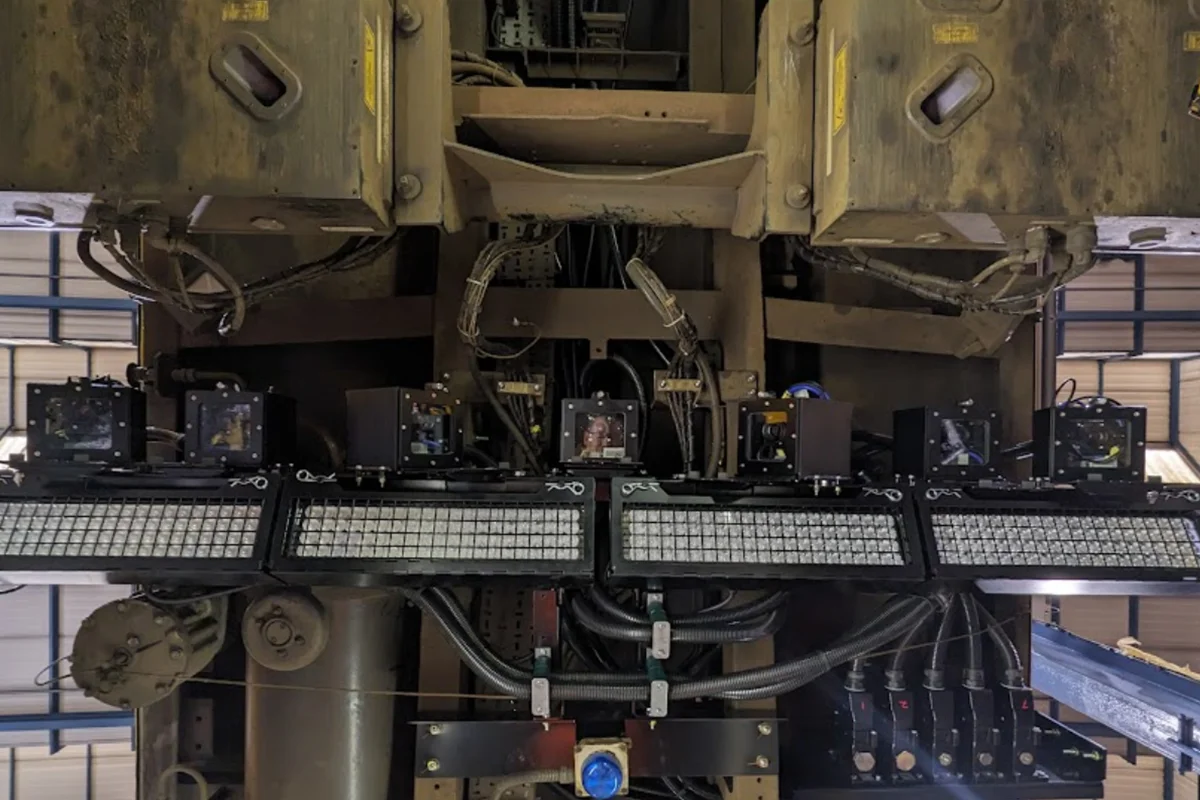

Diagram e.g. of AIVR camera positions on trains

The forward-facing video camera is perched on the front and looks at the track ahead; other cameras include ones located below the train, to photograph the track at close quarters. Ideally these cameras shoot images in which the whole frame is sharp.

These cameras have to cope with a wide variety of circumstances: there are rapidly altering light levels, caused by alternating light and shade, including flickering shadows cast by trees and the sudden darkness of tunnels. The weather is constantly changing and introducing anything from driving rain to freezing fog or snow, as well as shimmering heat and brilliant sunshine.

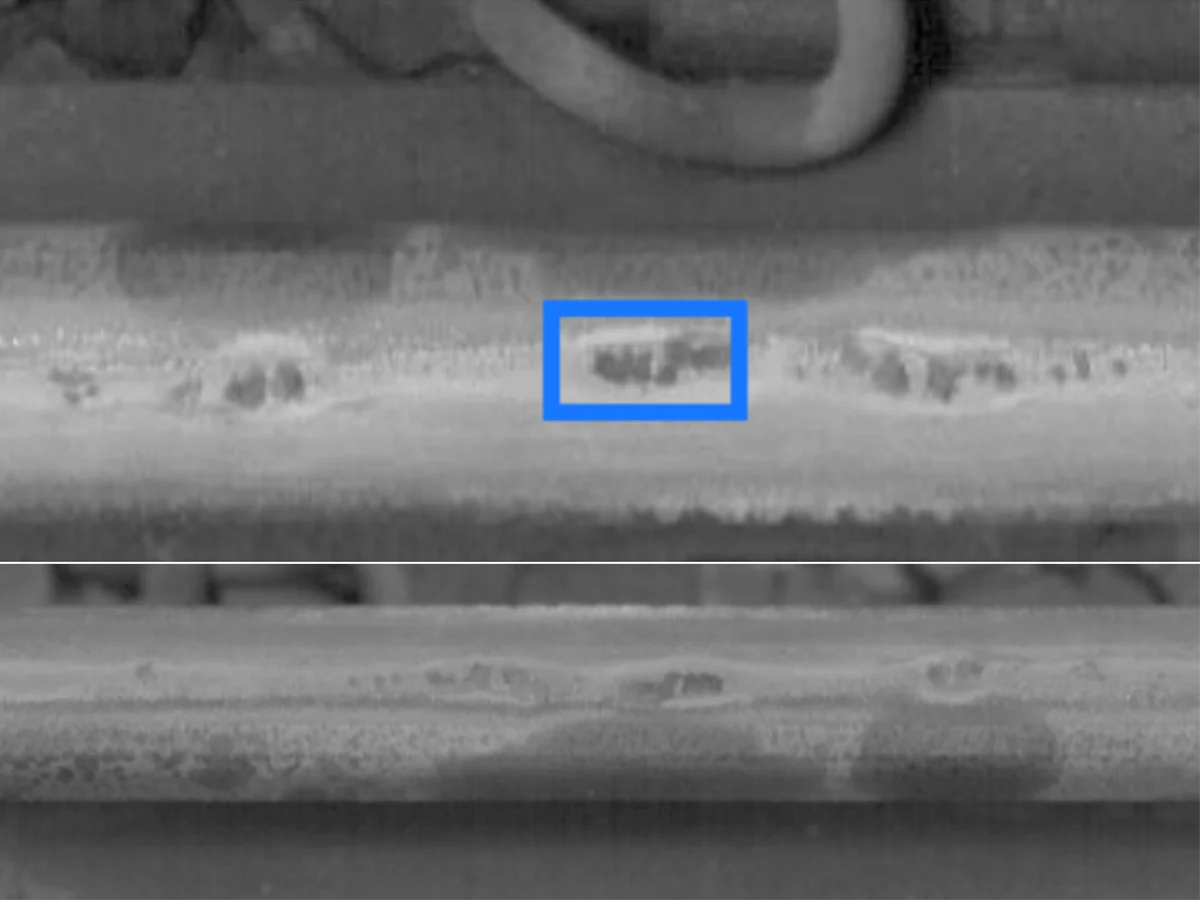

Rail in heavy fog (captured by AIVR)

Especially on the camera beneath the train, grit and dirt builds up on the glass that protects the camera. (OBC fits lights to illuminate the track beneath the train, but eventually they also get plastered in grime.) Then there are disturbances caused by the train itself, including vibration and electromagnetic fields.

Before (left) and after (right) camera clean

Before (left) and after (right) camera clean

The train is, obviously, moving; at different speeds, and sometimes very fast – which causes fresh challenges in creating sharp images that cover every millimetre of the rail network.

Finally, there are constraints on space, too. The front of a train includes windscreens, headlamps and sometimes a cab door or an emergency exit. Cameras must not obscure the train driver’s view, or inhibit any moving parts, especially those escape routes. So they must comply with conditions imposed by railway industry standards. This means that they have to be compact enough to fit, along with all other components, including power and cabling, into weathertight boxes of an agreed size.

Can’t cameras simply be maintained and configured to cope with all these variables, delivering good shots whatever the conditions?

Part 2: Seeking solutions

OBC’s starting point was to find the best possible equipment. In this endeavour as in all others, their approach has been rigorously empirical. One of the firm’s principles – inspired by the writer Nassim Nicholas Taleb – is We don’t put theories into practice, we create theories out of practice. So OBC tried stuff out.

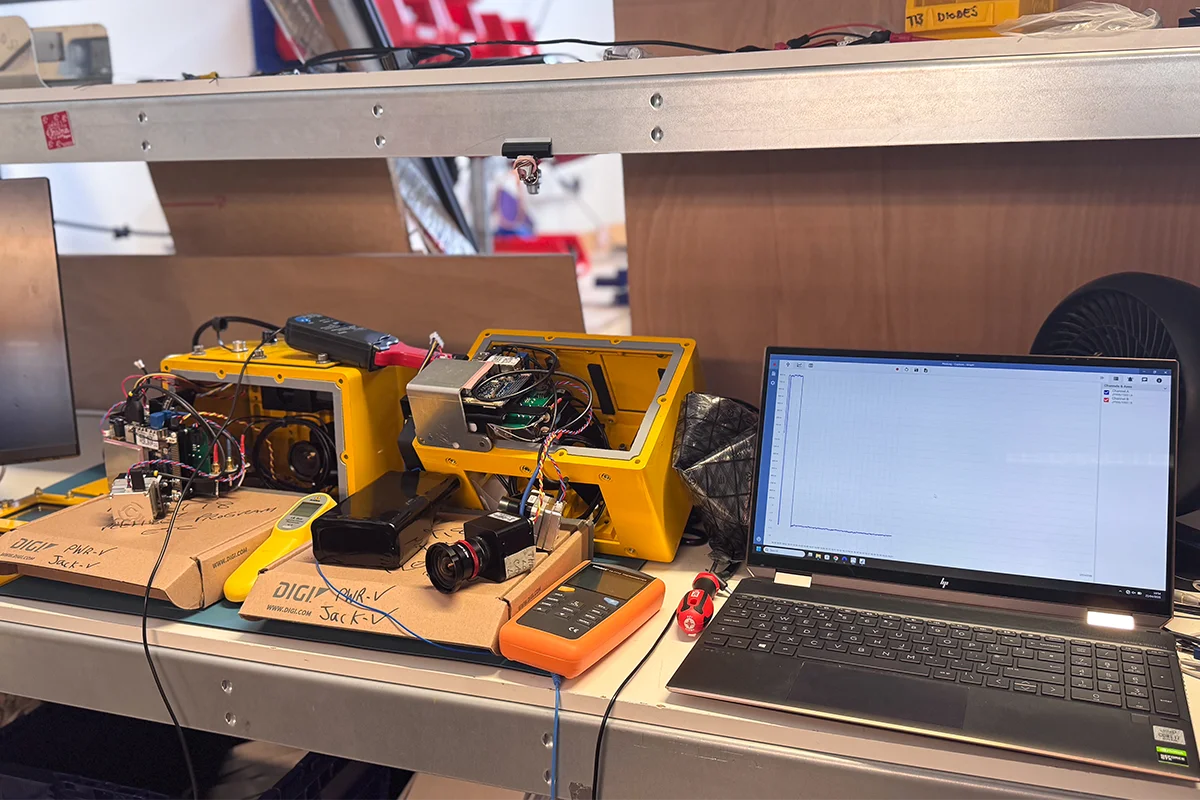

Since AIVR launched in 2019, One Big Circle’s engineers have tested around 100 different cameras, and are constantly acquiring more and experimenting with them, according to OBC co-founder Ian Packer.

Most of the cameras are compact. Industrial cameras like these look very little like an SLR or a hand-held video camera, which readers may be more familiar with. They vary but typically comprise a plain black box around 40mm square, which contains the sensor and processor; this is attached to a lens around 60mm long, says Ian.

Testing is crucial, he says, as the manufacturer’s claims must be backed up before cameras can be trusted to perform. “The maker’s paper product sheet is just a very rough guide on how good the camera’s going to be,” says Ian. “We are normally looking for something better than the best thing that is currently available, but until you get it in the lab, you can never be sure it will actually deliver.”

Testing

For forward-facing cameras OBC engineers do lab tests, or mount on the van to test at speed, according to Ian. “Cameras that make it through our lab and road-testing regime will then be tested in real trains where possible and as early as we can.”

But as Ian says, the starting point for the testing process is the lab at OBC’s office at Temple Studios, next to Bristol Temple Meads station. So let’s head back there now.

The lab occupies one end of the OBC office, which takes up much of the ground floor of a refurbished 1930s brick building that once housed offices of the Great Western Railway (before that, a train carriage shed stood on the site).

The lab contains a row of work benches, each surrounded by shelves and scattered with tools. There’s an abundance of Louvre-mounted wall panels from which hang dozens of plastic boxes in bright red, yellow and blue. Cables spill from some, test cameras from others; there are components and computers and plenty of mugs of tea to power the team. Test engineer Tracy, production manager Will and systems engineer George labour quietly at their benches.

Today, there’s a faint scent of freshly sawn pine in the air – another engineer, Harry, has been making a wooden frame to test the configuration of a seven-camera track-scanning system destined for deployment on an Ultrasonic Test Unit (UTU), one of Network Rail’s four specialized testing trains.

Testing tolerances of equipment is an important part of the lab’s role. Will and his colleagues have to demonstrate that equipment meets rail industry standards before it is fitted on trains. In this case, the relevant European rolling stock standard is EN 50155, which is designed to ensure that electrical equipment on trains is safe to use. “It requires that equipment insulation must be capable of taking a shock of 1,000 volts, so either you buy equipment that can be tested at that voltage, or build the system to ensure it passes those safety requirements.”

Vibration can also really mess up optical or electrical equipment, if it is not tough enough to cope. And of course there is plenty of vibration on trains. Uneven track surfaces, rail joints, switches and other imperfections in the rail cause the wheels to bounce and quake; irregularities in the wheels and throbbing diesel engines all cause vibration, too.

The engineers replicate these conditions in the lab before deploying gear to trains. While much equipment is sent away to test houses – remote labs with specialist equipment – to ensure it formally meets industry standards, almost all gear is also tested on the shake table in the lab. “We shake-test everything we build,” says Will.

Configuring cameras for the best results

Part of the lab’s role is to test not just the tolerance of cameras, but their ability to produce high quality images in demanding conditions. When testing cameras – and then setting them up for use on trains – OBC engineers explore many variables.

Anyone with access to a modern manual SLR camera will be aware of the huge number of different settings, starting with the ‘exposure triangle’: shutter speed, aperture and ISO. The first two combine to admit light through the lens; ISO is sometimes said to indicate the sensitivity of a sensor to light, but in fact indicates the degree to which the signal from the sensor is amplified (we’ll return to this below, under Sensors and ISO).

“The possible configurations of any given camera balloon not into thousands, but into trillions”

With each of these three elements there is a range of sub-settings. Aperture – which defines the size of the ‘hole’ admitting light to the camera – can typically range over several settings (f-stops) in any given lens. Likewise, ISO and shutter speed have a range of settings. But there are many other significant variables in the configuration of a camera. Add to these focal length, resolution, sensor size, frame rates, compression options, and the possible configurations of any given camera balloon not into thousands, but into trillions.

A small selection of the variety of lenses tested in-house

Sometimes clients ask OBC for the details of optimal camera settings, or ‘which lens’ the company uses. This seems a straightforward question but in reality, as I am learning, there is no straight answer. No one size fits all, confirms Ian. There are different lenses, cameras, and configurations depending on the use-case, physical constraints, and upload bandwidth limits.

Next, let’s go through in more detail some of the most significant variables mentioned above, and explain the theoretical difficulties OBC is up against in devising one configuration capable of delivering high quality images in all circumstances. Adjust any one of these variables, and there is always a trade-off – and these trade-offs become more marked as environmental conditions become more challenging, and especially as light levels decrease.

Shutters

OBC is usually recording images with video cameras, which use electronic shutters rather than mechanical mechanism. Electronic shutters create an exposure by effectively simply capturing the light falling on the sensor for a specified period. On the plus side, there are no moving parts to wear out – unlike the mechanical shutters traditionally used in still photography.

“When capturing moving objects, many cameras with electronic shutters create distorted images”

There is a snag, though. When capturing moving objects, many cameras with electronic shutters create distorted images.

That’s because the image is usually not recorded in one go, but line by line, from the top of each image down. In the tiny delay between completing each line of pixels, a fast-moving object in the frame will have altered its position slightly, relative to the camera. The effect on a train-mounted camera is that – for example – straight trackside posts appear distorted. This effect is called ‘rolling shutter’.

In contrast, ‘global’ electronic shutter sensors can record the whole image at once.

But so far, finding suitable global shutters has proved more difficult.

Why? “The people that make sensors and cameras – huge international companies like Sony and the camera supply chain – don’t make the exact products OBC wants, because they don’t need to.

“They produce sensors at huge volumes, mostly for phones and other consumer products that are sold in the hundreds of millions. Proportionately, the industries that need global sensors are minuscule in comparison. So global sensors don’t get the research and development priority.”

Aperture

So to avoid the image distortions caused by ‘rolling shutter’, can’t you just let more light into the camera in the first place?

As mentioned above, aperture is the word for the size of hole used to admit light through to the sensor. This hole mimics the human iris: a series of overlapping metal blades open and close by degrees as you adjust the f-stop on the camera. When light levels are low, you can widen the aperture to let in more light and achieve the correct exposure.

“Widening the aperture has another unavoidable effect on the image – it reduces the depth of field”

Unfortunately for OBC, though, this is a good example of the way that laws of physics affect the images.

That’s because widening the aperture has another unavoidable effect on the image – it reduces the depth of field, or the range of what is in focus in your shot.

So if OBC relied on widening the aperture in low light conditions, it would end up with images that were mostly blurry, except for a shallow band of sharp focus.

Note that depth of field is also affected by focal length and sensor size – our next subject.

Sensors and ISO

Would a more sensitive sensor help capture correctly exposed images in low light conditions?

After all, sensors are available in a range of sensitivity characteristics. One of these characteristics is how much ‘digital noise’ – a grainy effect in images – there is at different ISO levels.

Let’s briefly explore ISO. Back when photographers used film, the ISO rating reflected the film’s sensitivity to light, which was chemically established through film emulsion. An ISO or ‘film speed’ of 100 was thought considered standard and provided the highest quality, while a speed of 400 was better for lower light conditions, resulting in increased grain as a trade-off.

In modern digital photography, digital sensors have replaced film. While ISO remains relevant, its meaning has evolved. Rather than indicating the light sensitivity of a sensor, an ISO figure in digital cameras refers to the equivalent level of amplification of the sensor’s signal. It’s a bit like adjusting the volume on an audio system. It allows photographers to fine-tune the exposure of their images by boosting or reducing the sensor’s output signal. (For a more detailed explanation, read this feature from Canon’s Eos Magazine.

The trade-off is that in boosting ISO, noise (and therefore grain) becomes more likely. Performance varies; some sensors might reach an unacceptable threshold of noise at an ISO of 1,600 or above (equivalent to a poorly lit room) whereas others remain clean at even higher numbers.

“Partly thanks to its sensor, the mass consumer Sony A7S camera truly is astonishing in low light,” says Ian, “but unfortunately it is not technology we can access in industrial cameras.”

So what about using a larger sensor? Most camera sensors are just a few millimetres across – but the larger ones are several times the size, measuring a few centimetres across. These bigger sensors can capture more light, delivering correctly exposed images in lower light conditions. These images will always be of lower fidelity than images shot in bright light – but they might be good enough for OBC’s purposes.

Sorted, then? Unfortunately, there are currently a couple of serious drawbacks to large sensors.

First, a big sensor requires a big lens to project light on to a larger area. But as I mentioned above, space is tight. OBC is required to fit all forward-facing camera equipment into a steel box mounted on the front of the train – and that box is limited in size; and must contain cabling too. So a bigger lens simply might not fit.

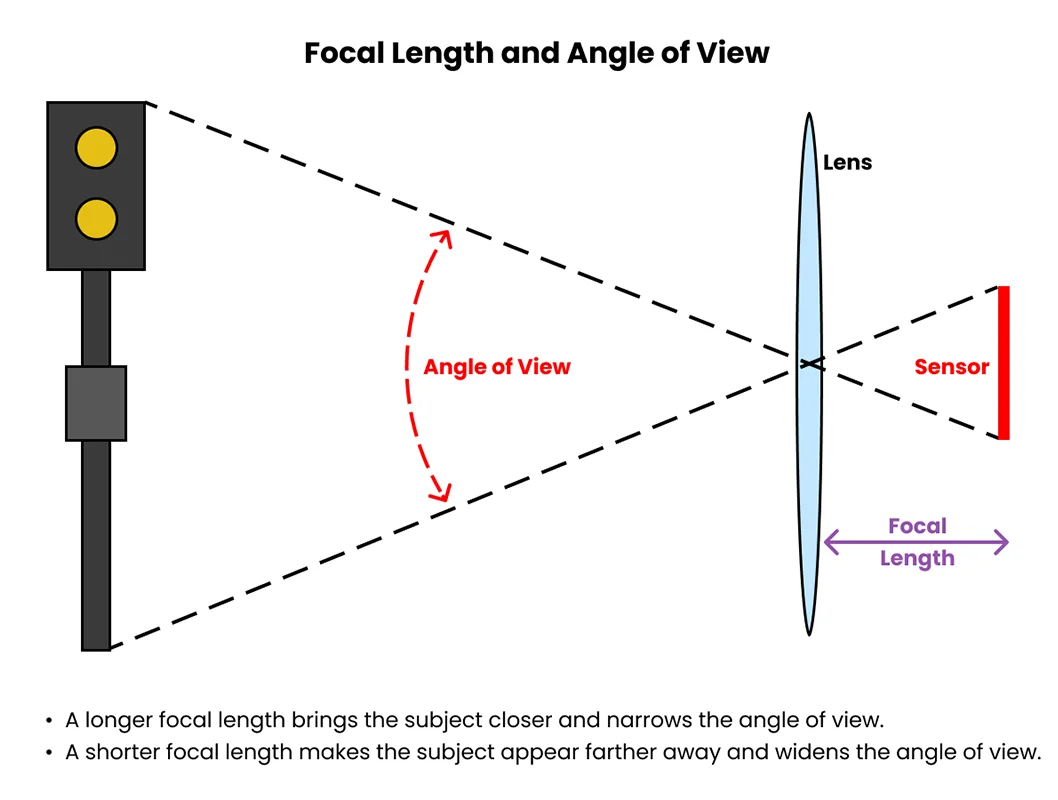

Diagram explaining Focal Length and Angle of View

Second, thanks to the physics of focal length and aperture, big sensors make the depth of field narrower – so less of the image is in focus. That might be a desirable effect in some photography, but not for OBC. On trains, as we mentioned above, it’s important to get as much in focus as possible.

Finally, assuming these difficulties could be overcome, the availability of large sensors in industrial cameras is problematic. “For manufacturers, it’s harder to engineer in the building of the camera, more technically difficult, and the market isn’t so much there for them in the format required by OBC,” says Ian. (The issues are similar to those affecting global sensors, mentioned above.) He adds: “Often times, when we test an industrial camera with a larger sensor, the hardware is significantly compromised in some other respect, such as maximum supported frame rate.”

PART 3: Solutions

To repeat the question that opened part 2 – can cameras be calibrated perfectly to always produce sharp, consistent images, despite the environmental challenges posed by light and weather?

The answer for present is no, says Ian. While cameras can be set up to function optimally in a specific situation, the footage they get will be useful for a specific task. A global solution remains out of reach. “You cannot have the optimal parameter for everything all at once,” Ian explains.

Ian is at pains to point out that the team is continually searching for the best quality camera hardware and software available. But, he adds, there is a kind of solution to the dilemma: acceptance. “You can’t have everything,” he emphasises, quietly fervent. “There will always be some degree of compromise.”

Paradigm shift

According to Ian, that compromise is to offset the quality of some images with volume.

The key to the AIVR strategy – the real paradigm shift – is that you can still acquire the information you need, provided you make a quantum leap in the amount of video you shoot.

“Our approach is to capture more and use less of it, rather than capture less and make it all perfect. If you collect a thousand hours of footage and only use ten per cent of it, you are going to have more useful footage than if you gather 100 hours of good footage through a one-off activity or scheduled capture. You get more authority from the scale of it.”

Britain’s weather may often be grim, but it is also changeable. Keep capturing video, and any duff footage shot in difficult conditions will soon be superseded by new footage – shot in better weather and brighter light, and with more useable results.

When you combine all the footage together, there are plenty of images of sufficient quality to maintain an accurate and highly detailed picture of the network.

In sum, OBC knows that camera technology has its limits in real-world conditions, so its engineers don’t sweat over a few imperfect images – as they don’t affect the overall result.

It’s a heuristic approach that is helping to transform rail safety, says Emily.

Of course, this approach creates a vast amount of data – in 2024 alone, more than one petabyte (1m gigabytes). That’s the data equivalent of 320 billion bibles. It includes four years’ worth of video footage, shot during more than a million miles of rail travel.

“You do have more data – but that’s a nicer problem to have,” says Ian. “Unlike the weather, it’s all under our control.”

In other words, OBC’s solution is to move the problem of image capture to the problem of managing and processing data – locating the valuable information locked up inside a vast quantity of footage. That sounds daunting but as Ian says: “Capturing loads of stuff makes the problem a solvable problem rather than an impossible one.”

“We process that data to get insights,” says Emily, “but because we share the data, infrastructure owners and their supply chain can also benefit from that visibility and access.”

So how can infrastructure owners get the best insights from the data supplied by AIVR, and share the data with others? That’s a whole other story…

Meet the expert

Ian Packer, Co-founder, One Big Circle

Ian is responsible for creating scalable digital video systems for Bristol technology firm One Big Circle, inventors of AIVR.

Now aged 40, Ian became a keen computer programmer at the age of eight. He started his career at North Somerset tech company Simulation Systems (SSL) in 2005. Ian’s work there increasingly involved video. “SSL did a lot of camera stuff – mostly traffic management and motorways,” Ian says. “Back then they were quite high-spec cameras,” he says – so he learned much from working with them.

After SSL, Ian became involved joined Bristol technology firm My Action Replay. The company’s innovative system allowed sportspeople to capture instant replays of their actions at the press of a button, from video cameras set up in sports halls, courts and other venues.

Ian co-founded One Big Circle (OBC) In 2017. One early OBC project involved working with long-range cameras, with a wide spectrum, in harsh operating conditions, for a defence contract. Ian’s work on the project added to his experience with high-end, high-budget industrial cameras. “It was an experiment in the art of the possible,” he says. “It gave me a deeper understanding of possibilities and limitations of the technology when budget is not a limiting factor.”

Two years later, Ian was once more integrating cameras into a wider system, with the launch of AIVR. He says AIVR is probably the eighth version of a large integrated software/hardware video system he has worked on. “They are all a bit different, but similar in some respects. And they’ve been getting better and better. Each time embarking on a new project we’ve been able to start from scratch but with all the lessons learned from previous projects.”

Meanwhile, Ian’s personal interest in photography has grown. Back when OBC was in its infancy, the first thing the company sold was actually a still photo – one of Ian’s images of Daly’s bridge in Cork, for an Irish firm organising a climate conference.

One of Ian’s pictures

In his mid-20s, intrigued by what he’d learned about cameras at work, Ian had begun to develop an interest in taking his own photographs. “The hobby side (of photography) is more about the art, rather than the technical side,” Ian says. Even so, it’s a two-way relationship, and the knowledge gained from his artistic work “bleeds back in” to the technical work. “The knowledge of how to get a photograph to look the way you want comes from the technical side – but the art side helps, too. Being able to look at an image and know exactly what’s wrong with it, a lot of that comes from taking pictures for artistic reasons.”

OBC co-founder Barnaby Kent said: “Ian knows what perfect looks like, but he also knows what’s achievable. He’s got high standards – but those standards also apply to delivering something. He’s a finisher, who understands the compromises you have to make in order to deliver.”

Who are One Big Circle

Bristol-based tech firm One Big Circle (OBC) specialises in video technology and artificial intelligence (AI). It was founded in 2017 by Barnaby Kent, Emily Kent, Sam Low and Ian Packer.

In 2019, OBC launched its Automated Intelligent Video Review (AIVR) system, which enables remote monitoring of Britain’s rail network through real-time video data collection and cloud-based analytics.

Based at Bristol Temple Meads Station, just 100m from the offices of pioneering rail engineer IK Brunel, the growing firm won the King’s Award for Enterprise in Innovation in 2024.

The company’s name symbolises the interconnected nature of its work, emphasising how technology connects people, systems, and data to improve efficiency and safety, according to Emily.