Brunel, Babbage and the rise of automation

Written by Joe Pontin.

For thousands of years, the advance of automation has transformed our lives by stages. As we stand on the brink of a new wave of automation, swept in by the Fourth Industrial Revolution, we look back at the history of automation in railways – ushered in by two of Britain’s greatest engineering brains.

The age of the engineer: as the Fourth Industrial Revolution gathers pace, engineers find themselves on the brink of transforming the world once more.

Rise of the machines

If, like me, you’re not from a computing background, it’s regrettably easy to take technology for granted. Successive waves of innovation have lulled us into a sense of inevitability. We have satnav, flatscreens, streaming services; many of us have smart speakers, fitness trackers and EVs. New and more capable mobile phones roll out every year; of course they do. Those tech folks are on it.

We forget what little we had, just a few years ago. The iPhone was only launched in 2007; in that year, a modest 61% of UK households had internet access, up from just 30% in 2000. (By 2024, 94% of us had both a smartphone and home internet access.)

Of course, for many software engineers, there is nothing inevitable about this rapid expansion of technology. They know how much hard work goes into every new gadget. Tech does not evolve by magic. Behind every innovation there are ingenious engineers working long hours, drinking a lot of black coffee, and solving problems.

The Fourth Industrial Revolution

As a journalist for more than 25 years, I’m well aware of the ways in which technology is profoundly impacting on traditional industries. Consumers are moving rapidly to digital media, disrupting the old print industry. (When was the last time you bought a newspaper or magazine?) Now the Fourth Industrial Revolution (AI, automation, robots, and more) is gathering pace, and the tide of technology is profoundly affecting many other industries, too – including railways.

What to expect from this article

It can seem challenging to grasp the detail of this new technology. That’s why Bristol tech firm One Big Circle asked me to bring some traditional journalistic storytelling and analysis to explain the innovative work they are doing in the rail industry.

“If rail inspection sounds a little dry to you, it’s worth noting that there are quite literally lives at stake here”

The aim is to explore the intricacies of what One Big Circle does, in a way that is intelligible and interesting to rail engineers, and software people – and really any curious-minded readers out there.

If you are the last-mentioned neutral reader, and rail inspection sounds a little dry to you, it’s worth noting that there are quite literally lives at stake here. Damaged rails have the potential to cause serious accidents. (Something that has certainly sharpened my appreciation of the efforts that go into making my train journey home along the tracks of North Somerset a safe one.)

Along the way, we’ll explore some concepts that I’ve found useful in better understanding the state of technology more generally as we enter the second quarter of the century.

As I’ve discovered in long conversations with the software engineers at OBC, over the last six years the firm has pioneered an approach that is transforming the ways rail engineers keep our train tracks safe. Unravelling and examining the interlocking ideas from which this technology is built have been fascinating to me – and will, I hope, interest you too, whatever your background.

The railway environment is complex – as this ladder of double slip points demonstrates. Since the beginning of passenger railways 200 years ago, engineers have used automated devices to understand it better. Photo by AIVR.

A note on structure

To understand the progress made by automation since 2019, I think it’s useful to understand the state of railway inspection technology before then – both its strengths and limitations.

So in part one of this article, I investigate the history of automation on our railways since the industry’s origins – a story that involves some of Britain’s greatest engineers.

From steam to diesel and electric eras, I will look at some huge leaps forward in rail inspection capability, and consider the constraints that were holding back improvements as the railways neared the end of their second century.

In part two, I aim to explain the engineering problems OBC resolved to create autonomous devices that are helping to transform the quality and quantity of available information about the state of Britain’s rail tracks.

Path to automation

Automatic for the people

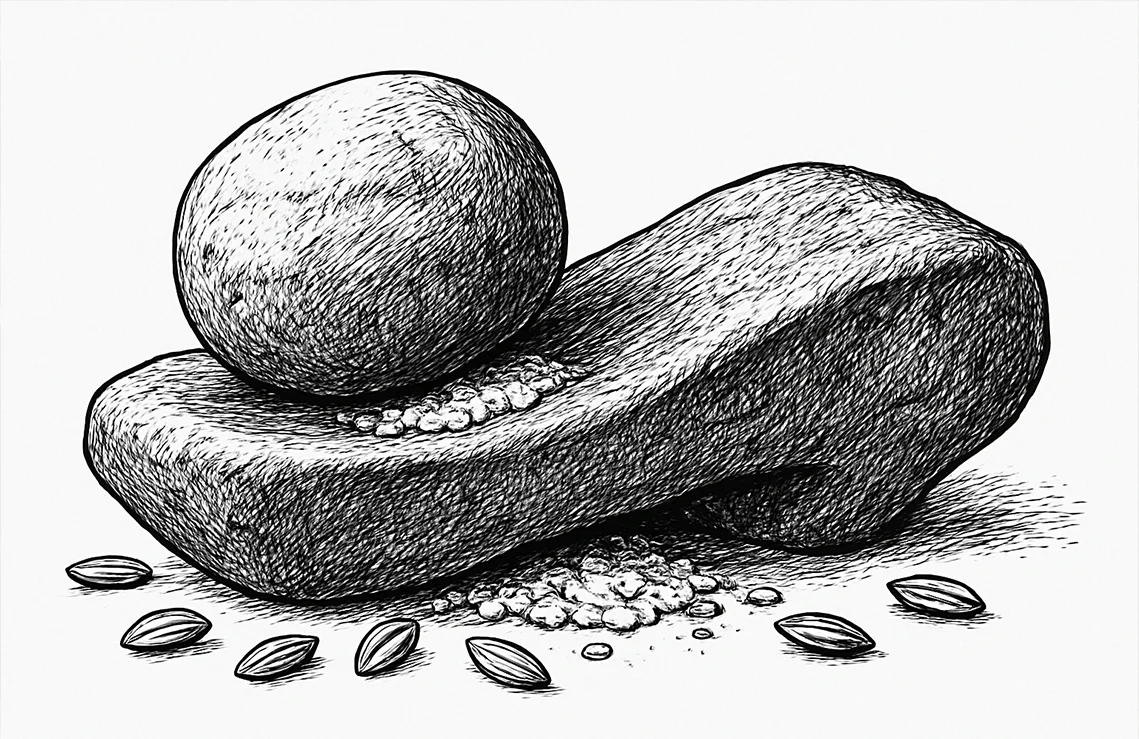

For 10,000 years, humans ground grains manually using quern stones, until automation liberated our ancestors with the invention of water mills.

“If we look at the whole arc of human history, the one thing that has systematically changed is that more and more gets automated” – Stephen Wolfram, physicist and computer scientist.

Just 12 miles southeast of Bristol, set beside the Conygre Brook and among the green fields of Somerset, lies a small group of old stone buildings. This is Priston Mill, where there has been a working waterwheel since 931, making it the oldest continuously operating mill in the world.

The origins of this technology, though, are much older. The ruins of ancient water mills can be found in what was Greek Byzantium, and date back to the third century BCE.

“If we look at the whole arc of human history, the one thing that has systematically changed is that more and more gets automated” – Stephen Wolfram

The water mill is one of the earliest forms of automation – using technology to perform tasks with minimal human intervention. It works by converting water’s kinetic energy into rotational energy, using a waterwheel and a system of gears to turn a runner stone over a stationary bedstone, grinding grain into flour.

The coming of the water mill meant that grain no longer had to be laboriously ground by hand. The amount of flour that one person could produce was dramatically scaled up, allowing our ancestors to set aside their querns and pounding stones and give more time to do other productive things.

Scaling up

Since the advent of the water mill, automation has become a fundamental driver of prosperity and economic growth. Its advance from the Industrial Revolution onwards has allowed humans to achieve things on a greater scale than ever before imagined.

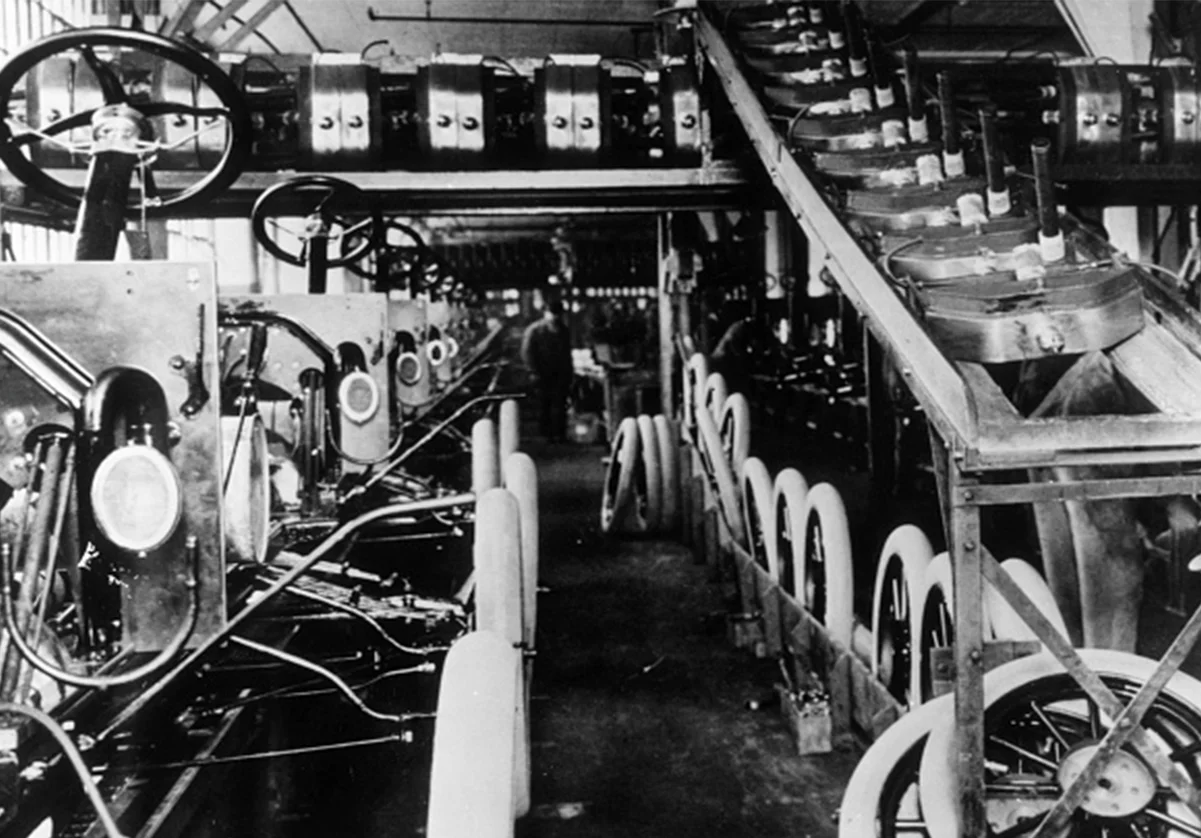

Perhaps the archetypal example of achieving scale through automation in manufacturing is the assembly line, first introduced by Henry Ford at the Highland Park factory in Michigan in 1913. Having divided the production process into smaller, specialized tasks, Ford wanted to maintain a continuous flow of work through the factory. So he automated the line itself, bringing the work to the worker at their station on the line. So even as each worker completed their specific task in the car’s manufacture, the vehicle was moving – pulled along the line using ropes (soon replaced by chains).

Ford’s moving production line helped the company scale up production from 170,000 in 1912 to more than a million in 1920. Photo by Hulton Archive/Stringer via Getty Images.

The results were spectacular: the production time for a single car dropped from more than 12 hours to just 93 minutes.

The assembly line was exceptionally adaptable to further automation over the years. In 1961, for example, Ford’s rival General Motors installed the world’s first industrial robot on its New Jersey assembly line. The Unimate took die castings and welding them onto vehicle bodies – sparing human workers from performing a task notoriously dangerous because of the risk of serious limb injuries and the presence of poisonous fumes.

Automation doesn’t always serve the immediate interests of workers whose roles are made redundant by automated technology. Some assembly line jobs became repetitive. But new jobs were also created.

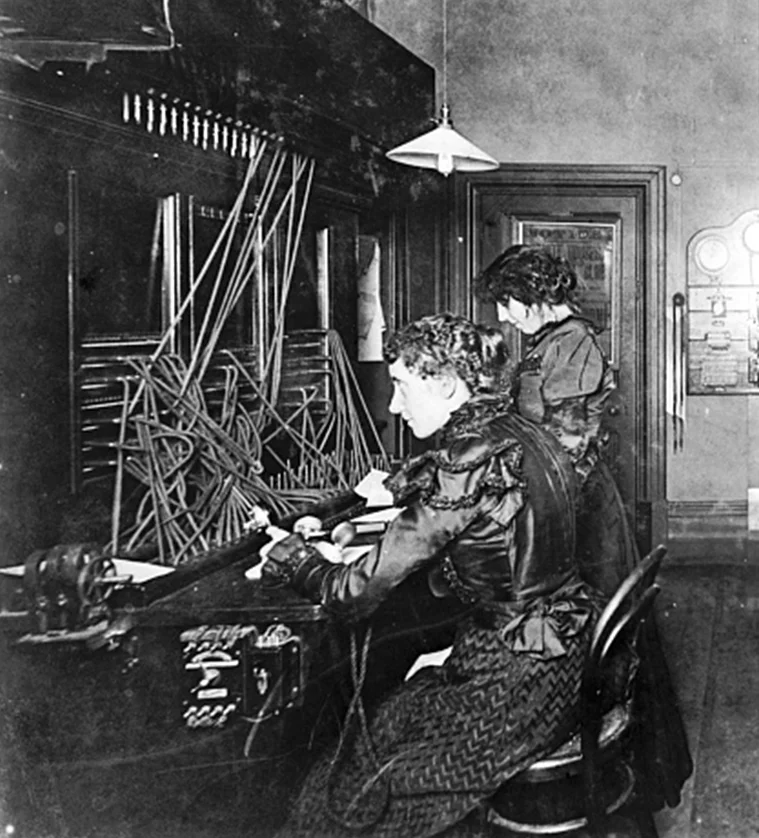

In 1905, telephonists known as ‘hello girls’ manually connected calls at telephone exchanges. Automatic exchanges, introduced from 1912, eventually led to the closure of the last manual exchange in 1960. Photo by Heritage Images/Contributor via Getty Images.

It’s worth noting that technological innovation has been changing the job market in a continuous cycle throughout the industrial revolution, and especially since the digital revolution that began in the 1970s. Economist David Autor and his collaborators recently found that 60% of employment in 2018 was in types of jobs that didn’t exist before 1940. It is likely that a significant proportion of today’s occupations will be displaced by new kinds of jobs in the future, too.

According to computer scientist Stephen Wolfram: “what seems to happen is that when one thing gets automated away, it opens up lots of new things to do, and as economies develop the pie chart of occupations seems to get more and more fragmented.”

Meanwhile, for the consumer, the car was transformed from a luxury to a common commodity, produced at scale. Automation in other industries likewise made other products – from washing machines to fridges – more affordable, and helped improved the quality of life for millions of people.

Automation had enabled scale. Manufacturers could now make a lot of stuff – at prices people could afford.

Automation on the tracks

New Measurement Train. Photo by mattbuck.

“The most technically advanced train of its kind in the world.” That’s how Network Rail described their New Measurement Train.

Launched in 2003, the scale of the NMT and its coverage was impressive. Travelling at high speed, it could monitor 115,000 miles of track in a year. It carried a crew of technicians using computer screens to monitor hi-tech test equipment that scrutinised the tracks, revealing potentially dangerous defects.

The NMT made a powerful case for the benefits of automation. Apart from the obvious wins in accuracy and efficiency, it facilitated a spectacular increase in the scale of inspection. In one day, the NMT could do the work of hundreds of engineers walking the tracks.

“From its early days, the rail industry has been associated with computing and automating”

Yet the idea of automation – using machines or computers instead of people to do stuff – was not exactly new to the railways. “From its early days, the rail industry has been associated with computing and automating,” points out Barnaby Kent, co-founder of OBC.

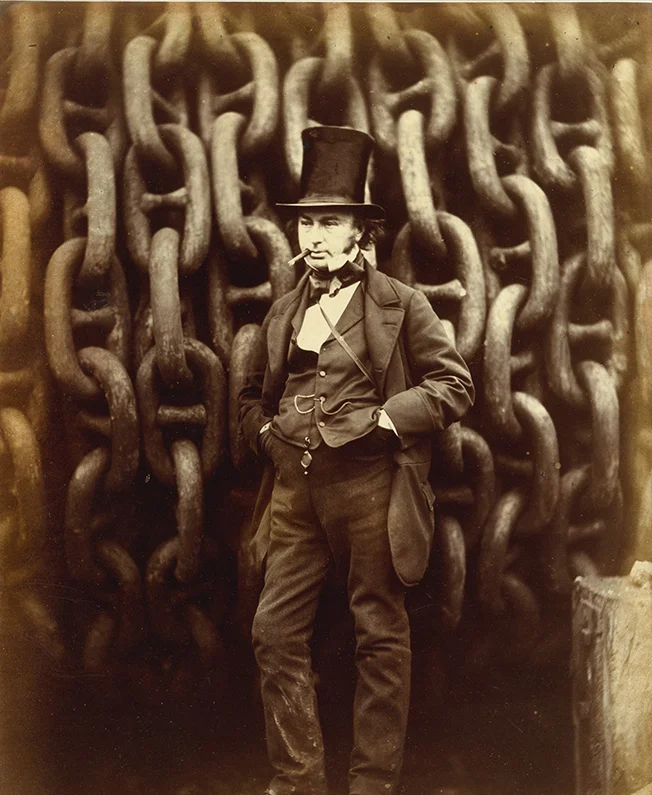

For as early as the 1830s – the decade in which railways really took off – automation was at the heart of an extraordinary collaboration between two men of genius: Isambard Kingdom Brunel, Britain’s greatest engineer; and Charles Babbage, the father of computing.

Automation from the Gauge War to the UTU

How far apart should railway tracks be? With the railway industry still in its infancy, it made sense to agree a standard track width, or gauge, on which all trains could run.

Railway engineer George Stephenson – the man behind the first steam-powered passenger service in 1825 – favoured 4-foot 8½-inches; Brunel, a quarter-century his junior, believed a broader gauge would deliver a more stable ride. So when Brunel started work on the Great Western Railway from London to Bristol in 1838, he laid tracks with a broad gauge of 7 feet ¼ inch.

To prove the superiority of the broad gauge, Brunel asked Babbage, his friend and an eminent scientist, to test the difference. So Babbage stripped back a passenger carriage and built what later engineers would call a vibration test rig, set on a long table. As Babbage later wrote, “On this table slowly rolled sheets of paper, each a thousand feet long. Several inking pens traced curves on this paper.” The pens recorded ‘force of traction’ and ‘vertical shake of the carriage’, while a chronometer marked half seconds on the paper. “Above two miles of paper were thus covered,” wrote Babbage.

“The result of my experiments convinced me that the broad gauge was most convenient and safest for the public,” concluded Babbage. Brunel was pleased with the results; but despite Babbage’s evidence, gathered during five months of research, Brunel eventually lost the gauge wars; and in 1892 the GWR’s broad gauge tracks were replaced with standard gauge.

Charles Babbage and Steampunk Computing

Even as Babbage conducted his experiments for Brunel, he was in the midst of two inter-related projects that secured his place in history as the father of computing.

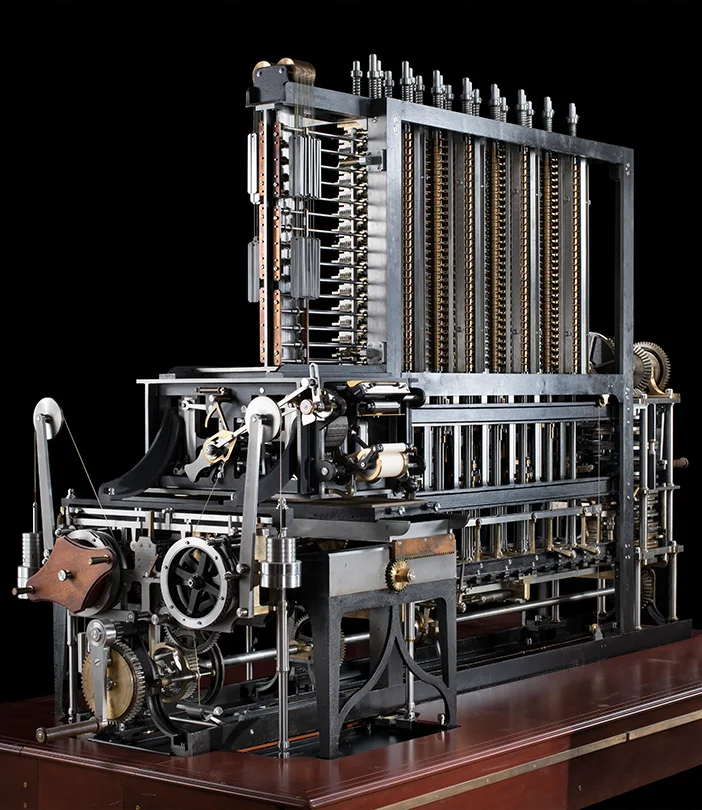

Babbage’s difference engine was a crucial breakthrough in the early history of computing, but was never actually completed – until 1991. Photo by Science Museam.

He had conceived and was attempting to build the Difference Engine, devised to compute and print accurate mathematical tables used in astronomical, navigational and engineering calculations. Hitherto, human errors would occur in the calculation, transcription, typesetting and printing of tables – mistakes that cost the government £2-3 million and even caused navigational mistakes that made ships run aground, according to Babbage. (‘I wish to God these calculations had been executed by steam,’ he had declared to his friend, the eminent mathematician John Herschel.)

Though uncompleted in Babbage’s lifetime, work on the Difference Engine cost the Treasury a whopping £17,500. The machine was finally built in 1991. Operated by cranking a handle, it measures 11ft long and 8ft high, weighs five tonnes and consists of 8,000 parts made of bronze, cast iron and steel. It performs complex algebraic calculations: figuring out and tabulating the value of any seventh order polynomial to 31 decimal places.

Powered by steam, Babbage’s Analytical Engine was to be even bigger and more complex, being capable of general-purpose computation. It was to be programmable, using punched cards, but again remained largely theoretical; while parts of the machine were built in Babbage’s lifetime, it has never been completed, despite some efforts to raise funds to this end in the last 10 years or so.

With all that paper and ink, Babbage’s automated testing may have been high maintenance by modern standards, but the results offered objective measurement from which comparisons could be made, and it established the principle that automation could provide better quality data about the railways.

Dynamometers

The Babbage test car also included a device to test the train’s power, invented by Stephenson in 1818. So Babbage’s test carriage came to be known as one of the first dynamometer cars (from the Greek dunamis ‘power’ + French -mètre, measuring). Over the next century and a half, train companies on both sides of the Atlantic built dynamometer cars to record train speed, power and other data.

Early dynamometers measured train power by calibrating the pull on the front coupler, deploying a system of springs as a scale. Just as in Babbage’s day, data on pull and velocity would usually be recorded on time-indexed paper rolls; power would later be manually calculated.

LNER dynamometer

Babbage’s influence lingered in a major leap forward in automation: the deployment of a mechanical integrator on the LMS dynamometer, built in 1912 for the Lancashire and Yorkshire Railway. The mechanical integrator produced more accurate test results, using mechanical means, in similar ways to Babbage’s Difference Engine (see box above).

State of the art in 1912, the Lancashire & Yorkshire Railway Company’s dynamometer car was in use until 1970. See it for yourself at the West Shed Museum in Butterley, Derbyshire. Photo by rossendalian2013.

Setting records

One summer morning in 1938, south of Grantham in Lincolnshire, a seven-coach train swept down Stoke Bank at an astonishing speed. A sleek blue blur, the locomotive was an Art Deco wonder, with streamlined curves inspired by Bugatti racing cars, and named, with characteristic English irony, after a duck.

The Mallard set a speed record unmatched ever since. Photo by Science & Society Picture Library/Contributor via Getty Images

When the Mallard pulled into London’s Kings Cross station later that day, fireman Tommy Bray and driver Joe Duddington – still grimy with soot and sweat – descended from their cooling locomotive and gathered with the gentlemen of the press among the brass gauges, timepieces and teak of the train’s dynamometer car.

The Mallard’s crew, Tommy Bray and Joe Duddington, pose for the press beside the Dynamometer car instruments that recorded the engine’s top speed. Photo by Fox Photos/Stringer via Getty Images.

It was a momentous occasion: for the dynamometer had recorded a top speed of 126 mph – a world speed record for a steam locomotive, which still stands today.

The London and North East Railway Dynamometer Car had been built in 1906, and remained in use until 1951; it can still be seen at the National Railway Museum in York. Its role in the triumph of the Mallard gives it a place in British engineering history.

The Mallard’s record-breaking journey was a publicity win for its owner, the LNER; and marked the climax of the Golden Age of British railways, when the big four railway companies competed for prestige – an age that was now almost over.

Other aspects of locomotive performance were also monitored by the dynamometer cars of the early to mid-20th century. The two operators on the LNER Dynamometer Car (see box), for example, also measured the amount of steam used per hour, and the superheater and smokebox temperatures.

In the late 1950s mechanical devices mounted on trollies were used to measure and record track geometry. But the next big step in automated track monitoring was a technology that allowed engineers to see inside tracks for damage invisible on the surface.

Ultrasonic testing

In November 1967, a crowded train struck a broken rail at Hither Green in Southeast London and derailed. In the disaster that followed, 49 people were killed. It was the sixth most deadly rail accident in the UK.

“The British Rail Board commissioned a new train that would represent a huge leap forward in inspection technology”

The Hither Green inquiry report published in 1968 recommended, among other things, better maintenance and improved track inspection and monitoring.

By this time, the LMS dynamometer was a veteran. She had entered service in another era, before the world wars: the same year as Robert Scott reached the South Pole; the first aeroplane flight over the Irish Sea; and the sinking of the Titanic. So the British Rail Board commissioned a new train that would represent a huge leap forward in inspection technology.

Despite its low-key appearance, the UTU represented a momentous leap forward in track monitoring tech. Photo by John Senior.

The Ultrasonic Test Train entered service in 1970, shortly after the LMS dynamometer was finally retired from the network, and remained on the tracks until 1994. It contained equipment capable of detecting internal flaws in the track – defects not visible to the naked eye.

Ultrasonic testing deployed high-frequency sound waves to scan the rails. Using probes that slid along the track, sound waves were transmitted into the rail, reflecting back a characteristic signal if they encountered a defect.

The tech was not especially new; ultrasonic testing had first been introduced in the USA in 1949, and by the 1960s, it had become a standard feature of the US railways.

The UK’s Ultrasonic Test Train brought systematic and enhanced inspection of the tracks to the country for the first time. Travelling at a maximum 20mph, the train could cover 120 miles in a single shift.

While it obviously represented a step forward in automation, the test train required significant staff resources. A team of onboard engineers was necessary to monitor the testing process. They required a staff vehicle with a mess area and bunk beds.

“With digitisation, the amount of testing increased through the 1980s to about 10,000 miles a year”

The job of processing data from the train was demanding. According to Philip C Johnson, an engineer whose recollections of the UTU1 can be read at railcar.co.uk, “It originally had its results recorded on continuous 35mm film. This was manually examined by film readers at an office in Paddington.” Perhaps unsurprisingly, “The task was very onerous and it was very difficult to get and keep committed staff to carry out this work. Consequently it was only possible to analyse about 2,000 miles per year.”

With digitisation, reports Johnson, the amount of testing increased through the 1980s to about 10,000 miles a year. Even so, data from the train reportedly had a reputation among track engineers for unreliability – workers sent to investigate defects reported by the train often could not find them, according to the magazine Rail Engineer, and “many track engineers lost confidence in the UTU.”

On top of that, the train was beginning to age and “the reliability of the unit was becoming a problem both electronically and mechanically,” added Johnson. The train eventually went out of service in 1994.

Hatfield prompts upgrade

As the millennium arrived, rail inspection remained a largely manual affair, but a traumatic event that autumn was to have enormous implications for the industry, and usher in a new era for inspection technology.

The derailment at Hatfield triggered the introduction of new track inspection technology. Photo by ADRIAN DENNIS/AFP via Getty Images.

In October 2000, a Great North Eastern Railway InterCity 125 train derailed near Hatfield in Hertfordshire, killing four people and injuring 70.

The subsequent investigation found that a section of track had fractured and fragmented into more than 300 pieces. The failure was caused by ‘rolling contact fatigue’ – microscopic tears in the rail surface caused by repeated high loading.

“The report highlighted strategy and practices that compromised safety”

The report found serious shortcomings in the inspection and maintenance of the line. Some areas of damage in the rails were oxidised, showing they had been present for some time. These and other signs of damage had not been reported after visual inspections. The report highlighted significant shortcomings in Railtrack’s maintenance strategy and practices that compromised safety.

Quite apart from the tragic loss of life, the injuries, and the impact on the bereaved, the disaster was enormously costly. Major track replacements were required across the rail network; by May 2001 overall costs and compensation had reached an estimated £733m.

A new fleet of monitoring trains

A new fleet of Ultrasonic Test Units rolled out onto the network soon after Hatfield disaster. Photo by Kevin Bates.

Soon after Hatfield, Railtrack and Network Rail, its successor from 2002, introduced three new Ultrasonic Test Units, with a fourth following in 2012.

The UTUs were equipped with more accurate ultrasonic equipment that began to detect more defects, according to Rail Engineer.

Like their predecessors, the UTUs were able to measure track geometry, assessing twist (where tracks are not parallel), cyclic top (dips in the rails, causing the train to bounce), and gauge (track width).

They also used lasers to find signs of wear in the rails, while ground-penetrating radar checked that tracks were sufficiently supported by ballast and sleepers, detecting irregularities up to two metres deep.

But the UTUs suffered from a significant drawback – they operated at a maximum speed of 30mph, and so could only be used when there were no service trains running.

The NMT: state of the art

Stuffed with track monitoring gear, the fast-moving New Measurement Train allowed the inspection fleet to cover far more track. Photo by Alan Padley.

Speed was not a problem for the NMT, which Network Rail added to their inspection fleet in 2003. As we mentioned at the beginning of our brief history of rail inspection, the NMT was, and is, fast – with a top speed of 125mph.

While ultrasonic testing was left to the UTUs, there was plenty of useful track testing gear on the NMT, with the number of sensors on board reaching 14, including vertical and horizontal actuators, gyros and accelerometers and lasers. From 2013, the NMT was fitted with a system called Plain Line Pattern Recognition (PLPR), which captured up to 70,000 images of the track every second, allowing it to spot, among other things, missing fasteners, excess ballast and ineffective rail clamps – all potentially dangerous track defects.

Coverage

With their slow speed, the UTUs were forced to operate either by night, or on track closed to other services. In contrast, the NMT’s speed allowed it to operate alongside normal services – hugely increasing the coverage the monitoring fleet could provide. The NMT alone covers 4,800 miles of track every two weeks.

So how often were tracks now inspected by the monitoring trains? That depends. Network Rail prioritised some lines over others – high-traffic, high-speed lines would get the most attention. Lines with less and slower traffic require ultrasonic testing at maximum intervals of 26 weeks, according to Network Rail’s standards (NR/L2/TRK/001 mod06).

Inspection transformed?

By 2019, Network Rail’s five monitoring trains had achieved some big gains. These hi-tech inspection systems had replaced manual inspections on 8,500 of the UK’s 20,000 miles of track, according to Network Rail.

The ability to spot early signs of damage and plan for maintenance work – what Network Rail called its ‘predict and prevent’ strategy – was delivering significant progress.

Rail breaks were now much rarer – less than 10% of the numbers experienced at the time of Hatfield, nearly 20 years earlier, for example.

Yet even as the fleet of monitoring trains seemed to have achieved a major improvement in the condition of Britain’s rail network, events had already begun to impact on these inspection methods. Some were long term trends; others sudden and life-changing developments.

Growing challenges

Demand rises

With passenger numbers rising, how could inspections be made without disruptive line closures? Photo by alice_photo.

For one thing, Britain’s railways were booming. Measured by passenger kilometres, rail travel more than doubled between 1985 and 2020, from 30.4 billion kilometres to 67.7 billion kilometres. (Since the dip caused by Covid pandemic, numbers have recovered to 60.1 billion kilometres.)

And measured by passenger journeys, demand had almost tripled in the same period (from 686 million in 1984/5 to 1,731 million in 2019/2020; after the pandemic, numbers had recovered to 1,612m by 2023/24).

To meet demand, there were more trains running. By 2019, planned passenger train services had increased by 24% since 2009/10.

With more people and more trains on the rail network, closing the tracks for inspection – both for trackside engineers, and slow-moving monitoring trains – was more impactful on passenger services than ever.

Safety: Boots off ballast

Despite safety measures, time on the tracks continued to pose risks to the safety of workers. Photo by Richard Sutcliffe.

Up to now, this article has focused on keeping passengers and crew safe. But the workers responsible for maintaining the network in a safe state for passenger trains are themselves exposed to risks when working on the tracks.

The risks posed by track workers have fallen significantly in the last century. In 1920, an astonishing 420 railway workers died on the network. By 2000, in contrast, annual fatalities had declined to single figures – but accidents continued.

On 3 July 2019, two maintenance workers, Gareth Delbridge, 64, and Michael Lewis, 58, were working on the tracks at Margam, near Port Talbot, when they were hit by a Swansea to Paddington train, with fatal consequences. It was a disturbing reminder that working in a trackside environment remained a relatively dangerous thing to do.

Within days of the accident, Network Rail had launched a track-worker safety task force, under Martin Frobisher, Network Rail’s group safety, technical and engineering director. “We will make it safer to work on or near the railway than it is today,” promised Frobisher. “Everyone should expect to get home safe, every day, and while our track record has been good and improving, there are still too many close-calls and that will be addressed.”

While much of the subsequent focus was on improving safety for engineers while on the track, Network Rail was also keen to reduce the numbers of workers on the tracks in the first place – or, in the industry parlance, to get ‘boots off ballast’.

With Network Rail keen to keep passenger services running by day, much inspection and maintenance work was done by night. Photo by ANBerlin [Ondré].

“Having the workforce not out and about while trains are running is a huge transition for the industry” – Jasper Roseland

According to One Big Circle engineering manager Jasper Roseland, this means that Network Rail needs to be much cleverer about inspecting, and must maximise the limited time they have on site, to undertake repairs rather than inspections. “Having the workforce not out and about while trains are running is a huge transition for the industry,” he says, “and we are only at the beginning of making sure that Network Rail is able to maintain the railway in a long term, safe, sustainable way.”

Pandemic complicates inspection

When the Covid 19 pandemic struck, social distancing rules posed serious problems for manual track inspection. Teams of workers could no longer travel in the same vehicle to the inspection site, hampering inspection work all over the country.

So events and changing priorities caused growing constraints on both the work of the monitoring trains, and threatening to limit the coverage and scale of data they were able to gather. And physical inspections were increasingly problematic, too.

Could the existing inspection technology somehow be adapted to overcome these difficulties? In doing so, it was seriously hampered by some inbuilt constraints. Let’s look at those next.

Inherent constraints on the monitoring train fleet

1 Limits of attended systems

The NMT is vastly more sophisticated than the Babbage dynamometer car, but one thing it has in common with earlier track monitoring technology: it remains an attended system. While elements of the NMT are automated, most require the presence of human operators.

The use of human operators inevitably introduces a series of constraints and dependencies. Their basic needs must be met, from toilets to heating and food facilities. The NMT has a mess car; the UTU1 even had bunk beds. Should any of these essential facilities fail, then the train may not be able to operate.

“The data they had gathered had to be laboriously removed and shared”

2 Sharing data: wires and wheels

In another key respect, the work of the monitoring trains remained rooted in the physical: data sharing.

After the monitoring trains pulled into their depots to complete their shifts, the data they had gathered had to be laboriously removed and shared. It was a matter of wires and wheels: first, plug a portable hard drive into the train’s computers and download the test data; then send the hard drive by courier to Network Rail’s processing centre for analysis. Any relevant information would then be couriered within 72 hours to one of 12 Regional Operating Centres, Network Rail’s centralized signalling and control hubs, which would coordinate a physical inspection of the relevant section of track, and organise any repairs needed.

Seeking solutions

Specialist monitoring trains deliver high quality data that remains extremely useful to Network Rail’s engineers, but they were unable to achieve up-to-date coverage across the whole network. These constraints inevitably limited both the amount and extent of data gathered by the monitoring trains – and the availability of that data.

By 2019, this track monitoring methodology was increasingly constrained by other priorities, including a busier network, and the need to protect railway workers by getting boots off ballast.

How could the industry escape these constraints? What kind of system would be able to deliver more data on the state of the rail network, more up to date – and affordably, too?

Before we go further on that question, let’s take a step away from the rail industry to take a broader look at technology in 2019, because something was afoot – something relevant not only to railways, but to the future of the planet.

A revolution in the air

Could the dramatic advances in Artificial Intelligence and related tech be used to help keep railways safe?

As the teens of the 21st century came to a close, technology stood at a threshold. A series of related technologies were beginning to coalesce, offering once unimaginable synergies. The potentialities seemed almost limitless, and the implications revolutionary.

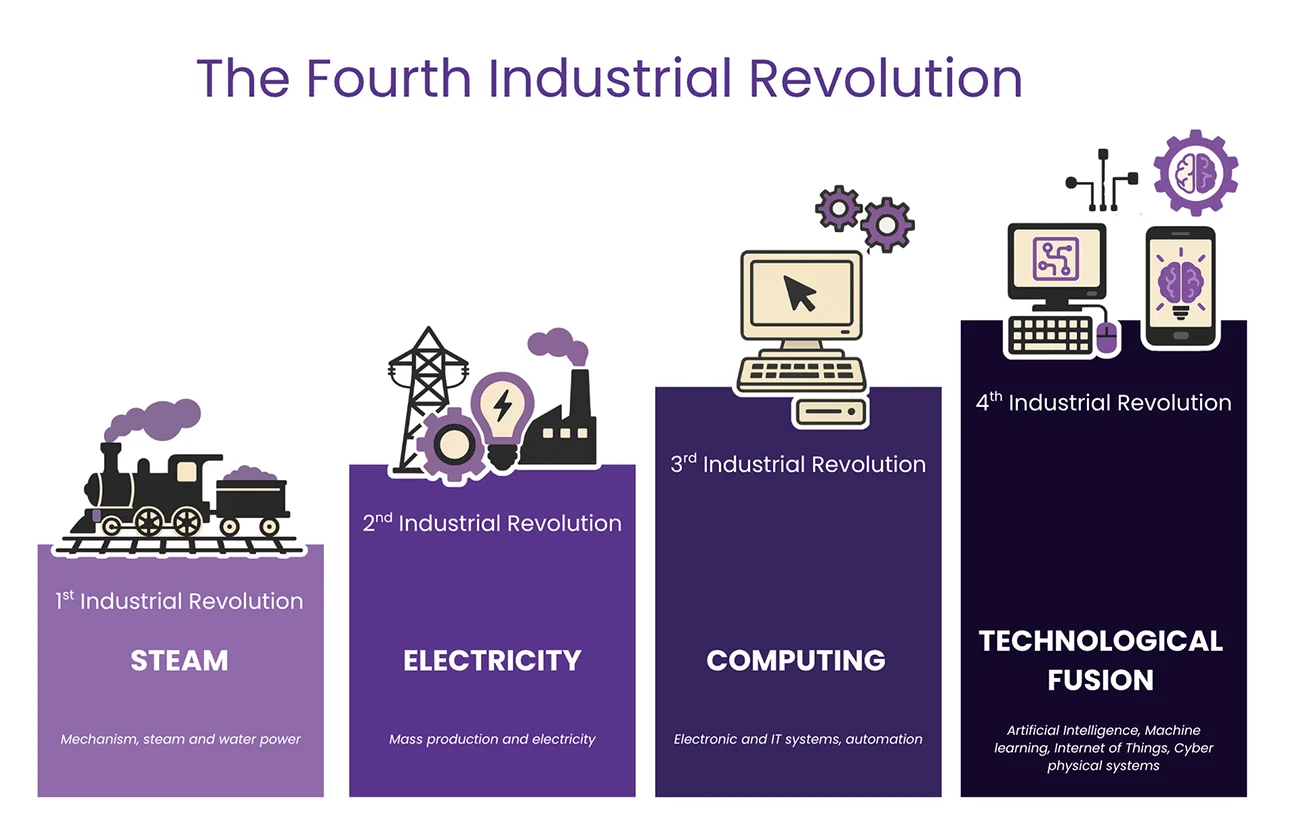

The term Fourth Industrial Revolution (4IR) had been popularized by Klaus Schwab, the founder and executive chairman of the World Economic Forum, with publication in 2016 of his book of that name. The 4IR is characterized by the fusion of technologies, including artificial intelligence (AI), robotics, the Internet of Things (IoT), and advanced materials, creating a world where virtual and physical systems cooperate. [If you’d like a quick reminder on the meaning of these terms, see box.]

The Fourth Industrial Revolution

The First Industrial Revolution brought steam power and factories; the Second, electricity and the internal combustion engine; and The Third, computers and the internet.

The Fourth Industrial Revolution 21st-century combines a series of technologies, including robotics and the following:

- Cloud computing – delivers on-demand computing services over the internet, offering scalability and flexibility in data storage and processing.

- The Internet of Things – refers to devices equipped with sensors, processing capabilities, software, and various technologies that communicate and share data with other devices and systems via the Internet.

- Big data and analytics – the collection and analysis of vast amounts of data to improve operational efficiencies and decision-making.

- Artificial intelligence – systems that can perform tasks typically associated with human intelligence, including learning, reasoning, problem-solving, perception, and decision-making. Machine learning is a branch of AI that focuses on enabling computers and systems to learn from data and improve their performance on tasks without being explicitly programmed.

The latest leap in technology may be the most consequential of all, according to some commentators.

Industry 4.0

The related idea of ‘Industrie 4.0’ or ‘Industry 4.0’ had been around since 2011, as part of the German government’s technology strategy, presented at the Hannover Fair that year. It aimed to integrate advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI) and robotics into manufacturing processes to create smart factories and improve efficiency. Subsequently it has been widely used as near synonym for the 4IR.

The technology that defines the Fourth Industrial Revolution has already begun to affect our lives. Chat GPT and other large language models are using AI to change our relationship with the written word, and with the web.

Other 4IT tech is ushering in an era of vastly increased automation. Among the most familiar to householders is the smart speaker, which uses the technology of the Internet of Things (IoT) to answer questions, or perform tasks via voice commands, or to control smart home devices such as washing machines, heating and security systems.

“Everything that moves will be autonomous someday, whether partially or fully.” – Jensen Huang

But that is just the beginning. According to Jensen Huang, CEO of leading tech firm NVIDIA: “Everything that moves will be autonomous someday, whether partially or fully.”

The applications of 4IR technology, and its prospective effect on levels of automation, have enormous potential, from fully autonomous cars and smart houses to smart factories, health services and advanced renewable energy systems – as well as yet-unimagined innovations. [Read more in our forthcoming article on Artificial Intelligence.]

Read more in part two

So… could the rail industry harness the wonders of the Fourth Industrial Revolution to transform rail inspection?

In particular, could the industry use automation to make a huge leap in the scale, quality, and (crucially) availability of data?

You can see how OBC responded to these opportunities in the second part of this article.