07/10/2024

One Big Circle Demonstrate New Rolling Stock Monitoring Solution at the Derby RTC

On September 18th, One Big Circle welcomed stakeholders from across the rail industry to the Derby Railway Technical Centre to showcase their groundbreaking DepotMATE (Multi-sensor Automated Train Examination) technology.

The DepotMATE project has been delivered in collaboration with industry partners Colas Rail, East Midlands Railway, and Transport for London through the 2023 Innovate UK First of a Kind competition. Responding to the competition’s theme of ‘Reliable and Maintainable Assets in Rail’, One Big Circle’s lightweight rolling stock monitoring solution captures extensive visible, thermal, and acoustic data to support on-site staff to remotely and safely monitor passing rolling stock.

DepotMATE unit installed at EMR Depot.

The demonstration day included a presentation of the DepotMATE technical journey, as it progressed from early concepts into a pre-production model now installed at two UK depots. Attendees heard directly from Richard Dare, Operations & Standards Manager at Colas Rail UK and Ben Field, Development Project Engineer at East Midlands Railway, who offered insight into the inspection and safety based challenges the DepotMATE project sought to address.

Presentations from Colas Rail UK, EMR and OBC team.

Members of the project team walked us through the testing, design, and manufacture of the DepotMATE system, which uses a variety of sensors to capture critical data:

- Visible Data – assisting with vehicle cleanliness assessments, recording historic vehicle data records, and assessing faulty or missing assets.

- Thermal Data – assisting with the monitoring of overheating assets such as wheel bearings, axle boxes, handbrakes, and blocked radiators.

- Acoustic Data – exploring the potential of identifying sounds attributed to wheel flats.

- RFID Data – an RFID antenna can be deployed to identify the passing vehicle.

DepotMATE Thermal and Visible image export example.

Those present were amongst the first to review the intuitive DepotMATE user interface, created as part of the end-to-end system. The web-based portal enables end users to access individual vehicle inspection data captured by installed DepotMATE units. The One Big Circle team demonstrated how owners and users of the system can easily search and filter vehicle data by RFID identification, date, location, or unit numbers, assisting maintainers to efficiently track and log inspections and monitor potential unit deterioration.

DepotMATE User Interface.

DepotMATE User Interface.

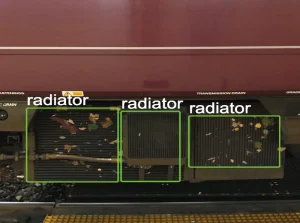

The team also demonstrated the system’s intelligent Machine Learning capabilities developed across the First of a Kind project. Applications currently include blurring visible faces where captured (drivers of each vehicle), identifying assets such as fuel caps and radiators, and capture of temperature exceedances (thermal ‘hotspots’) to progress automated reporting of overheating assets. The team shared real-world evidence of the system’s capacity to assist maintenance decision as a vehicular hotspot was found within a day of a DepotMATE installation, supporting the operator to take swift mitigating action.

DepotMATE Visible and Thermal AI examples.

Those who were present discussed how the lightweight and portable solution can be used in a modular “Plug & Play” manner, allowing different sensors to be configured and adjusted to fulfil customer and site-based requirements.|

Closing the session out, an insightful Q&A session was held to outline the future and next steps for the DepotMATE technology. The demonstration day marks the completion of the 12-month project, and the One Big Circle team are engaging with Rolling Stock operators, maintainers, and manufacturers to facilitate commercial trials of the technology in wider rail and transport depot environments.

If you are interested in testing a DepotMATE system to support your rolling stock inspections and operations, please get in touch with the OBC team by emailing enquiries@onebigcircle.co.uk