25/01/2024

Network Rail works with One Big Circle to explore Troughing Monitoring Solution

Network Rail experts have been working closely with One Big Circle technology teams to monitor and improve the UK Railway through remote infrastructure monitoring, increasing efficiency and safety by reducing boots on ballast.

Cable Route Automated Visual Examination

Network Rail and One Big Circle have recently worked collaboratively on R&D funded project CRAVE – Cable Route Automated Visual Examination, which addresses challenges related to the maintenance of rail infrastructure, specifically troughing. It supports Network Rail’s “Boots off Ballast” strategy to minimise on-site inspections and improve safety, aiming to automate troughing detection and assessment and expand remote inspection capabilities with a quick turnaround.

Troughing is used on the railway to protect cables (signalling, telecoms and power) for critical lineside assets (e.g. signals). If not actively maintained, troughing can become weathered and cracked or can become weathered and cracked or can be displaced. Vegetation or excessive ballast levels can also hinder the ability to access troughs for both maintenance and when adding new cables. As a result, these cable routes must be consistently monitored to ensure that they stay in working condition, protecting the cables inside, and in turn, the critical line side assets.

Historically, troughing and cable inspections face many challenges. The existing approach to monitoring the condition of troughing on the UK railway is a very manual and labour-intensive process, and it is difficult to keep track of the location and type of these routes. Subsequently, this “boots on ballast” approach put staff on site, which has an inherent safety risk, and is both time-consuming and costly from both a planning and preparation perspective.

As part of the Network Rail R&D programme in CP6 One Big Circle was selected by the Wales & Western Region Telecoms team to explore if it was possible to combat these challenges nationally utilising the AIVR Platform. The automation of these tasks would increase productivity, reducing boots on ballast, in turn reducing costs and simplifying maintenance and planning for remote asset inspection.

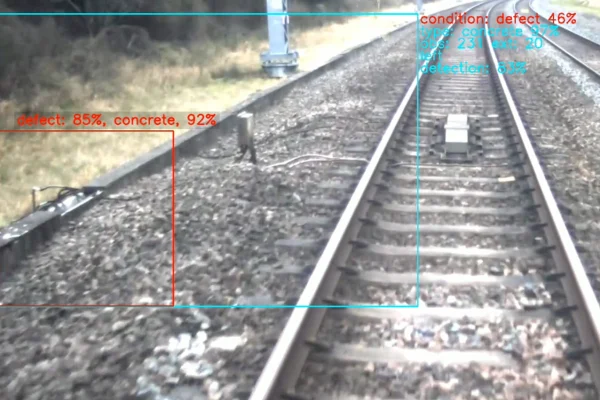

The CRAVE project uses Artificial Intelligence and Machine Learning to identify and classify troughing, using existing real-time infrastructure monitoring forward-facing AIVR video data. This performs an automatic identification of troughing, alongside detections of existing classes currently available in AIVR (e.g. Signals, Structure ID PLates, Balance Weights).

After troughing has been identified, AIVR then assesses the condition and type of each section of troughing, performed using two image classification machine learning models. The ‘condition’ of the troughing is assessed by classifying each section as ‘Good’, ‘Defect’, ‘Obscured’ or ‘Cables outside of troughing’. Additionally, the ‘type’ of the troughing is assessed by classifying each section as ‘Concrete’, ‘Composite’ or ‘Elevated’. These classifiers assess every troughing detection, and the combined results effectively condense tens of thousands of individual troughing detections over many miles of track into a much more manageable form.

Results from this assessment are presented to the user in One Big Circle’s AIVR Platform, allowing users to review the information and imagery. The interface is designed to allow the users to quickly identify and evaluate troughing conditions, alongside the location of the troughing. The results can also be exported by the users and presented in an open format through PDF reports or Excel Spreadsheet reports, which can be shared with other parties and downstream tools for interpreting and accessing the data, enabling the data to be used for multiple purposes.

Richard Cundy, Regional Telecoms Asset & Performance Manager, Wales and Western Region, speaks on the project:

“Network Rail owns and maintains troughing running alongside the majority of the 10,000 route miles of the national rail network. This troughing houses signalling, telecoms, electrical and third-party cables and therefore it is important that the route is maintained to prevent damage to the cables within; any damage could lead to safety & performance issues on Britain’s railways, as well as leading to the company paying out any commercial liabilities to third parties.”

“We have recently updated our maintenance standard for cable route, reducing the need to physically walk the route and subsequently take “boots off ballast”. As a result of this change, there was a challenge to clearly identify where the cable route was located and find automated ways of identifying defects in the route, due to the reduction in maintenance resources. Having had experience with using AIVR, we approached OBC to see what they could do to assist us with this, knowing that they had already developed a method of capturing other lineside assets. Having obtained funding from NR’s R&D budget, a 6 month contract was let with OBC for them to research what could be achieved. Although I was initially sceptical that OBC could meet our challenge, I have been absolutely amazed at the work that has been done. As a result of the AI work undertaken by OBC, our knowledge of the location and condition of our cable route is now easily accessible, which will help us prioritise our maintenance and renewals for many years to come.”

Adam Williams – Asset Engineer (Telecoms), Wales and Western Region, said:

“Network Rail has to be accountable for how it prioritises it’s funding whilst also minimising the risks that the workforce are exposed to. Following on from the tragic events of Margam, and then cab riding restrictions as a result of COVID we had the need and opportunity to update the Cable Route maintenance standard. The main changes allowed colleagues to be taken out of harm’s way through the use of train borne video footage in lieu of on-track patrolling.”

“Project CRAVE sought to develop the integrated machine learning feature within the AIVR to identify cable route using the ready stream of video footage captured by the plethora of devices scouring the network daily. Once identified, cable route is then classified by type before its scanned for defects. A member of staff can than check the report that’s generated, verify the defects, and build the remedial work into a work bank. A process that could easily take days can be completed in a fraction of the time, allowing us to build up or renewals and minor works portfolio for the appropriate levels of funding as it becomes available.”

Nick Stone, Senior Asset Engineer, Telecoms (Support), Wales and Western, adds:

“I genuinely believe it will become an essential tool for Network Rail to deliver its maintenance obligations with regards to cable route, and will enable us to focus on defects and rectify them in a more time effective and cost-effective manner.”

The remote-enabled inspection of troughing is a testament to the collaborative effort of R&D between Network Rail and its suppliers, with One Big Circle pioneering the integration of Artificial Intelligence in railway asset management with real-time, custom-trained models for greater efficiency and safety in maintenance operations.